Industry 4.0 is the digital transformation of manufacturing/production and related industries and value creation processes.

Industry 4.0 is used interchangeably with the fourth industrial revolution and represents a new stage in the organization and control of the industrial value chain.

- Industry 4.0: the essence explained in a nutshell

- Data and optimization across the value chain

- Origins and history of Industry 4.0

- Industry 4.0 definitions – what is Industry 4.0?

- Industry 4.0 and the fourth industrial revolution (4IR)

- Industry 4.0 and the Industrial Internet

- The state of Industry 4.0

- Benefits of Industry 4.0

- Industry 4.0 strategy and implementation

- Cyber-physical systems: the building blocks of Industry 4.0

- Industry 4.0 building blocks: the (Industrial) Internet of Things

- Reference Architectural Model Industrie 4.0 (RAMI 4.0)

- Industrie 4.0 principles: horizontal and vertical integration

- Horizontal integration in Industry 4.0

- Vertical integration in Industry 4.0

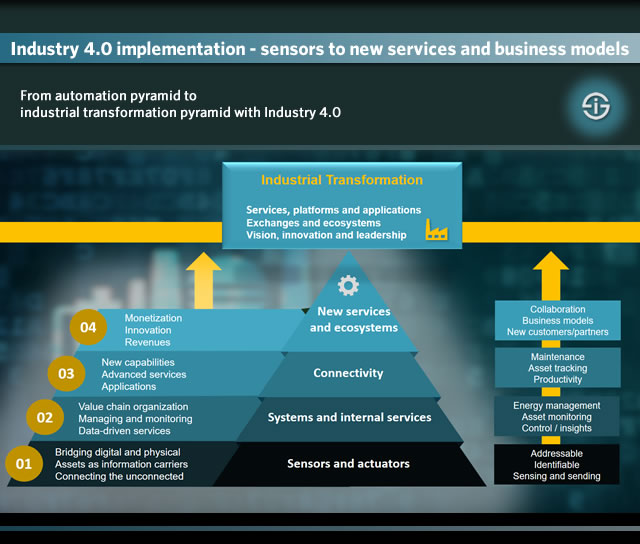

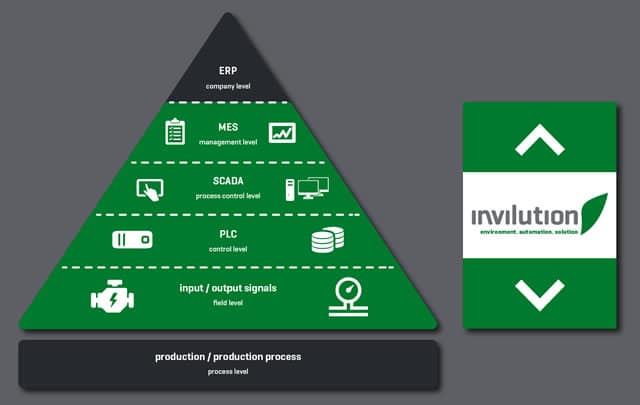

- The automation pyramid and new business models in Industry 4.0

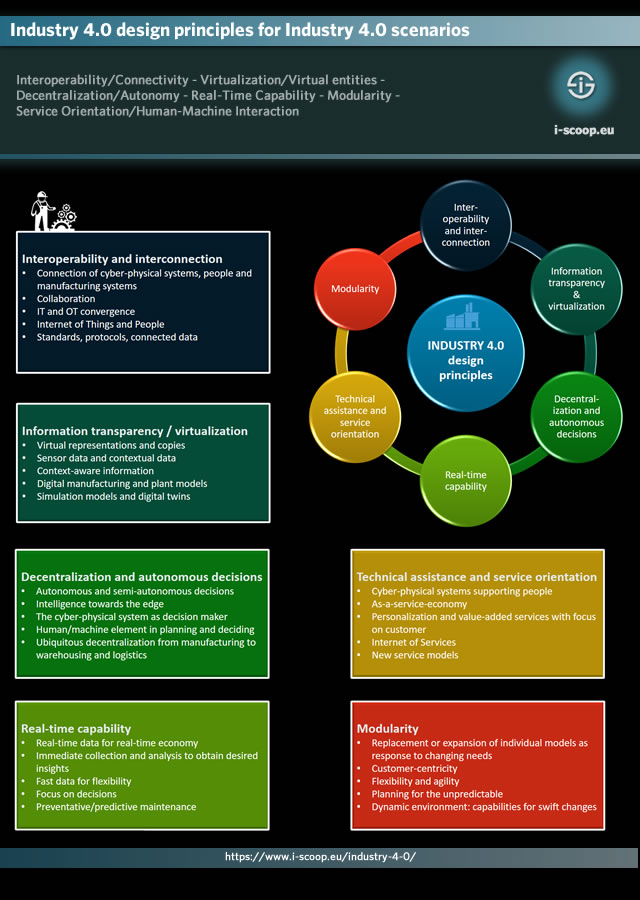

- Industry 4.0 design principles

- Interoperability, interconnection, connectivity

- Information transparency, virtualization and virtual entities

- Decentralization, autonomous decisions and autonomy

- Real-time capability

- Technical assistance and service orientation

- Modularity

- Industry 4.0 and technologies

- Beyond the automation pyramid: disrupted application levels

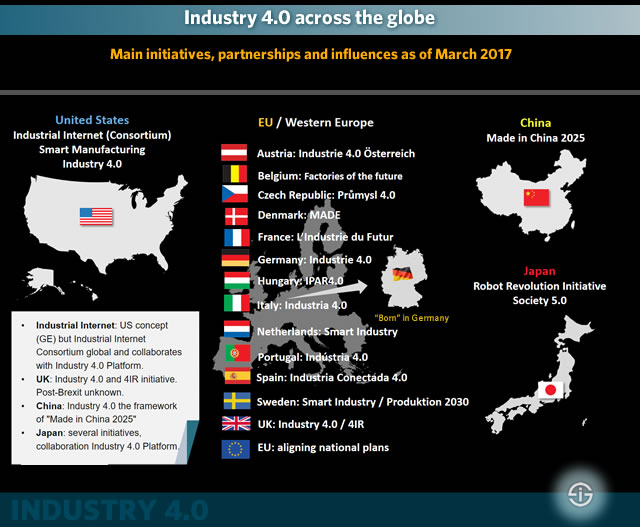

- Industry 4.0 initiatives and evolutions around the world

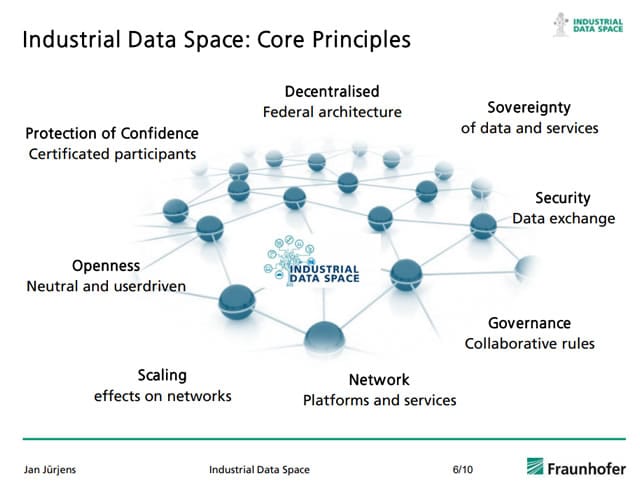

- Industrial Data Space

- Industry 4.0 FAQ

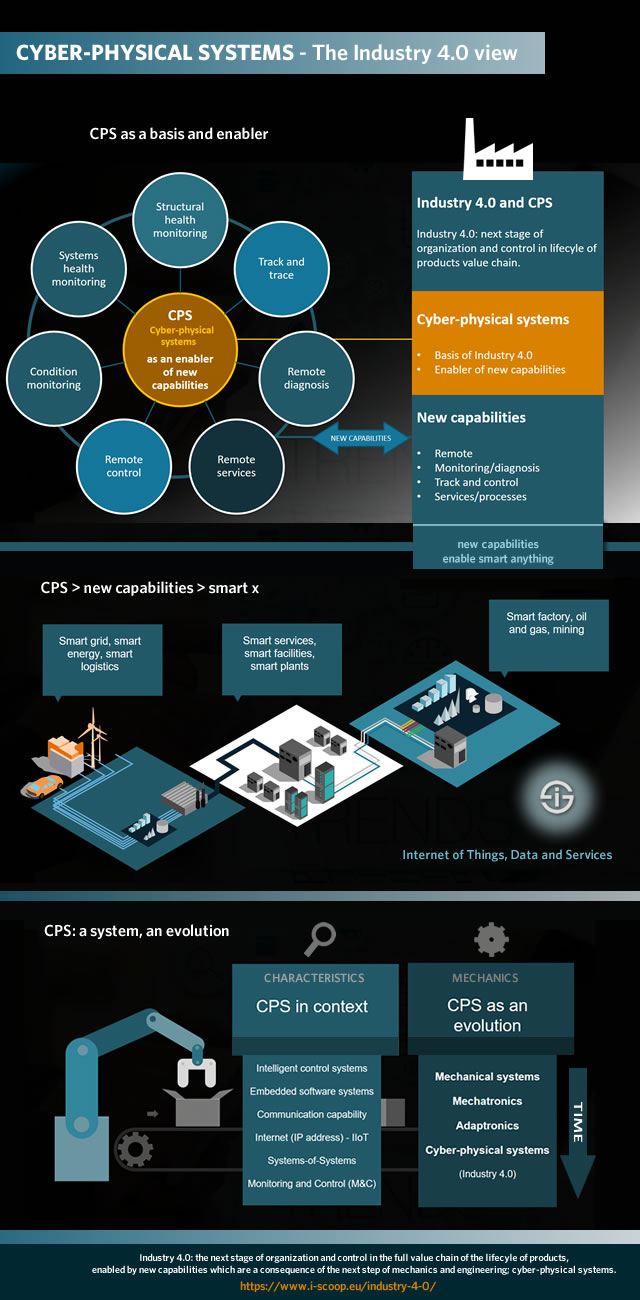

Cyber-physical systems form the basis of Industry 4.0 (e.g., ‘smart machines’). They use modern control systems, have embedded software systems and dispose of an Internet address to connect and be addressed via the Internet of Things (IoT).

This way, products and means of production get networked and can ‘communicate’, enabling new ways of production, value creation, and real-time optimization.

Cyber-physical systems create the capabilities needed for smart factories. These are the same capabilities we know from the Industrial Internet of Things like remote monitoring or track and trace, to mention two.

Industry 4.0 has been defined as “a name for the current trend of automation and data exchange in manufacturing technologies, including cyber-physical systems, the Internet of things, cloud computing and cognitive computing and creating the smart factory”.

Industry 4.0 is a vision that evolved from an initiative to make the German manufacturing industry more competitive (‘Industrie 4.0’) to a globally adopted term.

Industry 4.0 is often used interchangeably with the notion of the fourth industrial revolution. It is characterized by, among others,

Industrie 4.0 refers to the intelligent networking of machines and processes for industry with the help of information and communication technology (Plattform Industrie 4.0)

- even more automation than in the third industrial revolution,

- the bridging of the physical and digital world through cyber-physical systems, enabled by Industrial IoT,

- a shift from a central industrial control system to one where smart products define the production steps,

- closed-loop data models and control systems and

- personalization/customization of products.

The goal is to enable autonomous decision-making processes, monitor assets and processes in real-time, and enable equally real-time connected value creation networks through early involvement of stakeholders, and vertical and horizontal integration.

Industry 4.0 is a vision, policy, and concept in motion, with reference architectures, standardization and even definitions in flux.

The fourth industrial revolution and the impact of the drivers and technologies behind Industry 4.0 have been looked at from the perspective of various sectors after the concept was launched. This has led to more ‘4.0’ terms, often based on academic work. Examples include Logistics 4.0 (logistics and transportation), Construction 4.0 (construction industry), Energy 4.0 (energy and utilities industry), and more.

Most Industry 4.0 initiatives are early-stage projects with a limited scope. The majority of digitization and digitalization efforts, in reality, happen in the context of third and even second industrial revolution technologies/goals.

At the very core Industry 4.0 includes the (partial) transfer of autonomy and autonomous decisions to cyber-physical systems and machines, leveraging information systems.

In essence, the technologies making Industry 4.0 possible leverage existing data and ample additional data sources, including data from connected assets to gain efficiencies on multiple levels, transform existing manufacturing processes, create end-to-end information streams across the value chain and realize new services and business models.

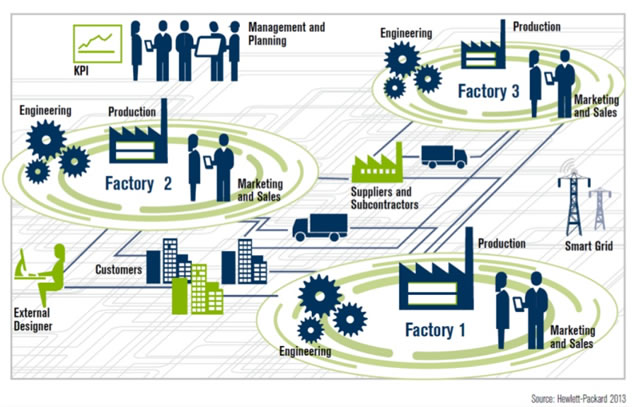

To understand Industry 4.0, it is essential to see the full value chain which includes suppliers and the origins of the materials and components needed for various forms of smart manufacturing, the end-to-end digital supply chain and the final destination of all manufacturing/production, regardless of the number of intermediary steps and players: the end customer.

Enabling more direct models of personalized production, servicing, as well as customer/consumer interaction (including gaining real-time data from actual product usage) and cutting the inefficiencies, irrelevance and costs of intermediaries in a digital supply chain model, where possible, are some goals of Industry 4.0 in this customer-centric sense of increasingly demanding customers who value speed, (cost) efficiencies and value-added innovative services.

In the end, it remains business – with the innovative twist of innovation and transformation of business models and processes: increase profit, decrease costs, enhance customer experience, optimize customer lifetime value and where possible customer loyalty, sell more, and innovate to grow and remain relevant.

Industry 4.0: the essence explained in a nutshell

Industry 4.0 is the information-intensive transformation of manufacturing (and related industries) in a connected environment of big data, people, processes, services, systems and IoT-enabled industrial assets with the generation, leverage and utilization of actionable data and information as a way and means to realize smart industry and ecosystems of industrial innovation and collaboration.

So, Industry 4.0 is a broad vision with clear frameworks and reference architectures, mainly characterized by the bridging of physical industrial assets and digital technologies in so-called cyber-physical systems.

A key role is indeed played by the Internet of Things or IoT, in the scope of Industry 4.0 Industrial IoT with its many IoT stack components, from IoT platforms to Industrial IoT gateways, devices and much more.

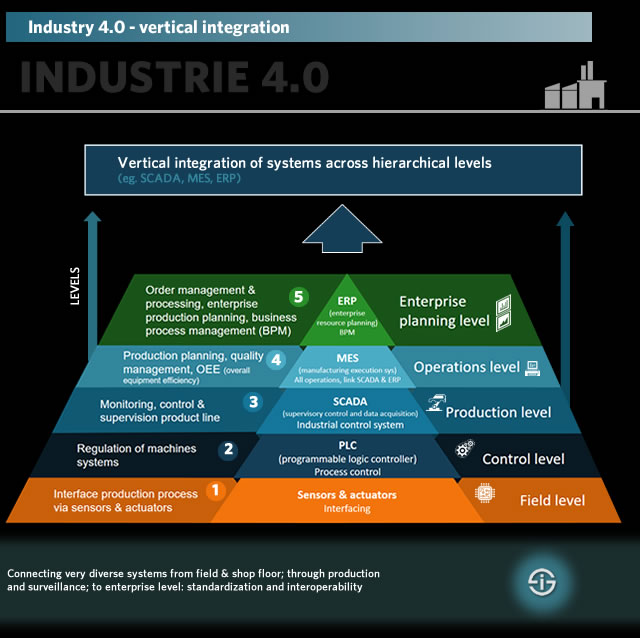

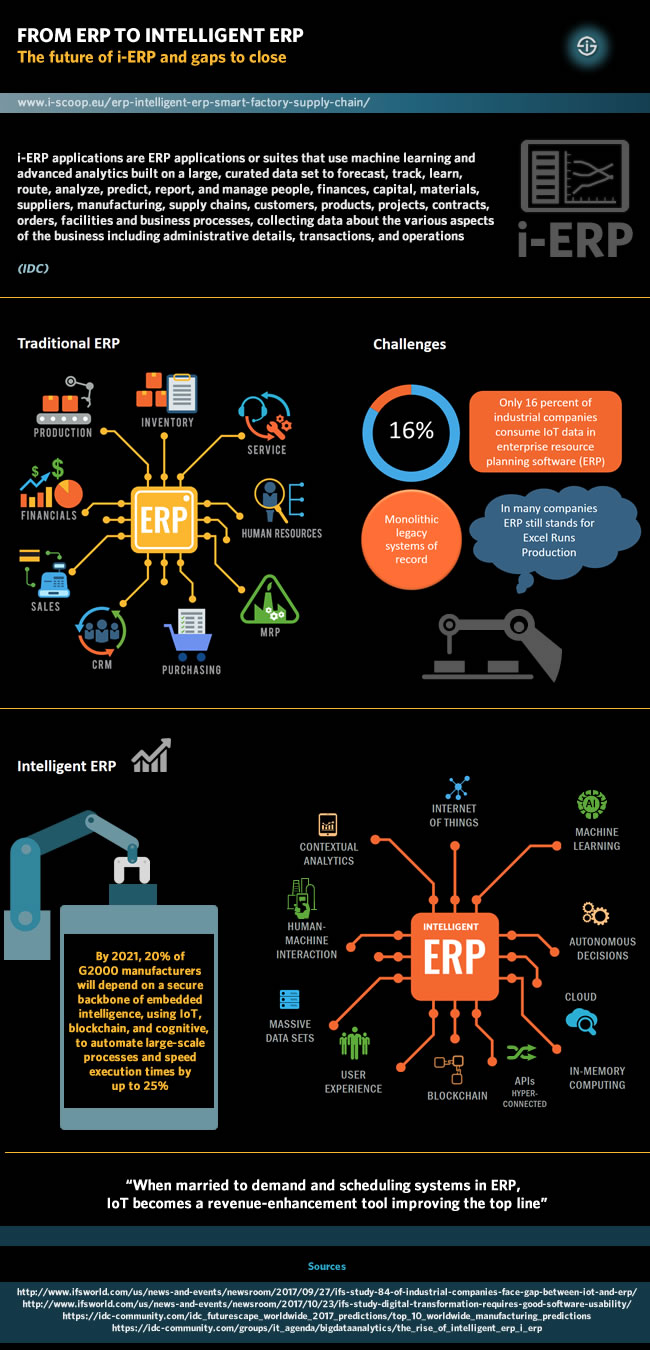

Yet, it’s not just IoT of course: cloud computing (and cloud platforms), big data (advanced data analytics, data lakes, edge intelligence) with (related) artificial intelligence, data analysis, storage and compute power at the edge of networks (edge computing), mobile, data communication/network technologies, changes on the level of, among others, HMI and SCADA, manufacturing execution systems (MES), enterprise resource planning (ERP, becoming i-ERP), programmable logic controllers (PLC), sensors and actuators, MEMS and transducers (sensors again) and innovative data exchange models all play a key role.

Additionally, the same technologies, such as Robotic Process Automation (RPA), AI (machine learning, generative AI, computer vision, agentic AI, etc.), the meeting of both and so forth that pop up in close to all software areas such as enterprise information management, business process management and applications in the sourcing market are of course showing in IoT-enabled industrial/manufacturing applications and IoT manufacturing platforms as well.

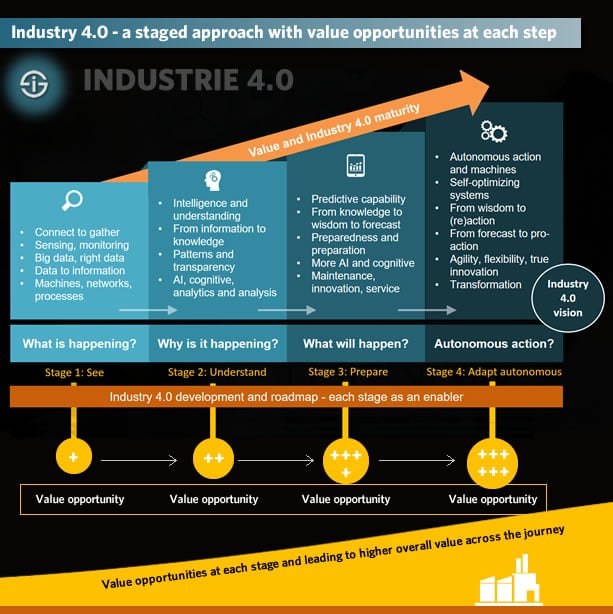

Industry 4.0 is not ‘something’ you realize overnight. Just as is the case with IoT deployments you need a strategic and staged approach.

This is exactly the same as with digital transformation strategy and gets covered in depth when we look at Industry 4.0 strategy and implementation and at the state of Industry 4.0 and maturity of organizations as they move from initial stages and pilots to more innovative approaches on top of the traditional low-hanging fruit in terms of optimization and automation. If you are in a hurry, there is a chapter on Industry 4.0 maturity models and roadmaps.

Data and optimization across the value chain

As you will discover in this guide Industry 4.0 is conceived as the next stage of organization and control in the full life cycle of the product value chain.

The cyber-physical systems are the basis and enable new capabilities in areas such as product design, prototyping and development, remote control, services and diagnosis, condition monitoring, proactive and predictive maintenance, track and trace, structural health and systems health monitoring, planning, innovation capability, agility, real-time applications and more.

These latter capabilities also lead to the types of use cases and deployments as well as the benefits of industry 4.0 which we cover later and include personalization capabilities, real-time alerts and interventions, innovative service models, dynamic product improvement, increased productivity, higher up-time and, ultimately, new business models.

The new capabilities of Industry 4.0 lead to the ‘smart anything’ phenomena which often get most attention: from smart grid, smart energy and smart logistics to smart facilities, including smart buildings, smart plants, and smart offices to the mentioned smart manufacturing, smart factories, smart cities and so on.

Industry 4.0 is the evolution to cyber-physical systems, representing the fourth industrial revolution on the road to an end-to-end value chain with Industrial IoT and decentralized intelligence in manufacturing

The cyber-physical system, its components (e.g. intelligent control systems and embedded software systems) and its place in the evolution of manufacturing and industry (starting from mechanical systems) is explained in depth in this guide.

Industry 4.0 builds upon data models and data mapping across the mentioned end-to-end product life cyle and value stream. All the technologies in Industry 4.0 need to be seen in that perspective whereby integration is key.

A first integration (or convergence) is that of information technology (IT) and operational technology (OT).

Without IT and OT convergence there is no industrial transformation, let alone modern building management and several other areas where the silos between different traditional systems dissapear due to, among others, IoT on one hand and where IT and OT meet on the other, which is the case in close to all industries. The essence of IT and OT convergence revolves around data (and the systems where they have been sitting for many years), processes and people/teams. Again, IoT is key here as also the Internet of Things starts with the capture (and subsequent analyses/leverage of data). It is safe to say that Industry 4.0 is only possible because of IoT. The technological essence of Industry 4.0 sometimes is also called cyber-physical convergence.

Since the convergence of IT, OT and their backbones (such as networks and infrastructure, whereby we can also add CT or communication technologies) essentially boils down to an advanced and enhanced application of Internet, IT technologies and IT infrastructure impacted by IoT data (cloud infrastructure, server infrastructure, storage and edge infrastructure etc.) many see Industry 4.0 as a continuation of the third industrial revolution.

On the other hand, the impact of ongoing automation in all organizations, including factories, has a clear impact on work and society. Yet, here as well it is argued that this is merely a result of the next steps in the third industrial revolution where automation already was intensive on many levels. Regardless of those discussions it’s clear that the fourth industrial revolution aspect of Industry 4.0 has won the debates.

Integrations in Industry 4.0: vertical and horizontal integration as all systems change

Further in this guide we will explore the two key integrations in the Industry 4.0 model.

The first is vertical integration whereby all the systems in the traditional automation pyramid are affected: from field level and control level to production level, operations level and enterprise planning level.

Vertical integration will make the traditional automation pyramid view disappear. The same goes for several systems and applications across these various levels. Other systems such as ERP will dramatically change while still others will be replaced by rapidly emerging applications in the scope of Industrial IoT platforms, specifically manufacturing platforms and vertical platforms for various tasks and use cases in the many aspects of industry that get ever more features and become combined in an interoperable ‘systems of systems’ approach and by digital transformation platforms and business applications where IoT platforms and functionalities get integrated into.

The second is horizontal integration which is not about the hierarchical view of several systems as in vertical integration but about the mentioned end-to-end value chain: from supplier and the processes, information flows and IT systems in the product development and production stage to logistics, distribution and ultimately the customer.

This too impacts the various systems employed in industrial markets and in the end is all about data and how, why and where it is used at the right time and right place for the right reasons to paraphrase the good old mantra of information management and business intelligence experts, with on top of course the good old DIKW model; from data to knowledge with the additional layer of action: decisions. And in Industry 4.0 that means human, semi-autonomous and autonomous (although it’s best to see it as a continuum)

An additional element that is key to mention in this quick introductory overview is indeed that of semi-autonomous and autonomous decisions, cornerstones in both Industry and Logistics 4.0, the essence of the self-organizing plant and autonomous production vision and, ultimately, the dream of as much automation as possible with IoT, artificial intelligence, the new integrated systems, advanced analytics and so forth all playing a role.

It directly touches upon what we cover next: Industry 4.0, technologies and workers whereby the view is one of augmented capabilities, different skills, savings on human labor and so on, whereby the promise is one where workers with ‘obsolete jobs’ will find other work (emphasis ‘the promise’ as until now significant job losses have been the result of automation).

Industry 4.0: technologies, security, people/workers and society

Before diving into all the mentioned evolutions, integrations, cyber-physical evolutions, IoT elements, big data aspects and before looking at the origins of Industry 4.0, definitions, evolutions, global implications, similar initiatives, Industry 4.0 design principles, building blocks and the Reference Architecture Model Industrie 4.0 a final word on technologies and people to wrap up this quick introduction.

With Industry 4.0, distributed data storage will become one of the main challenges in terms of security (Umsetzungsstrategie Industrie 4.0)

It is important to note that Industry 4.0 is not just about those technologies. It also looks at the impact on and role of society and workers (e.g. collaboration between man and machine as with collaborative robots or cobots, new required skillsets of factory workers amidst all these changes and, inevitably, the loss of jobs due to ongoing automation as mentioned – and how to tackle this major challenge). Still; many feel that the ‘human touch’ is not emphasized, hence the notion of Industry 5.0.

Moreover, Industry 4.0 also has a strong focus on security. This does not just mean security of data and communication networks, data protection (including personal data protection, especially since the arrival of the General Data Protection Regulation, the ePrivacy Regulation and coming rules in several areas, including green facilities, energy and ecology, and again personal data in the wake of scandals that have emerged in consumer markets), cybersecurity in the broadest sense and industrial control systems security (ICS security) but also the protection and security of workers, industrial assets, critical infrastructure and ‘physical security’.

As industrial assets and critical infrastructure (from critical power buildings to energy grids and more) get connected and attacks are on the rise in the traditionally rather isolated industrial environments the stakes and dangers of vulnerabilities and attacks are huge in industry 4.0 which requires an end-to-end ‘security by design’ approach. Since attacks increase and the consequences can be high it’s also recommended to not just focus on cybersecurity but to combine this with digital risk management, business continuity and other fields in what’s also known as cyber resilience and becomes a must as we keep transforming.

This overall security challenge and certainly the ICS security and end-to-end cybersecurity challenge ranks high among the Industry 4.0 challenges and risks. Moreover, cyber-physical systems and IoT are important factors in the rapid rise of external attack surface management per Gartner. And, last but not least, as is the case with digital transformation, industrial transformation is an ecosystem play. De facto this means tighter integrations with ever more partners and other stakeholders: third parties that come with additional opportunities but also ever more risks, leading to more attention for third-party risk management (TPRM).

On an Industry 4.0 technology level, finally, on top of the mentioned technologies (or rather groups of technologies) such as IoT, big data, IT, OT, several security technologies (industrial cybersecurity, visual monitoring of critical facilities, wearables to monitor worker safety in hazardous environments), artificial intelligence (AI), cloud, edge, fog and more you can add: additive manufacturing and 3D printing, digital twins, virtual and augmented reality (also in the context of digital twin simulation), advanced (AI) robotics and cobots, autonomous production, rapid application development, autonomous production, consistent engineering across the entire value chain, thorough data collection and provisioning, systems integration (cfr. vertical and horizontal integration), a vast range of networking and communication technologies, integration and connectivity standards/protocols, ways to make various IT and OT protocols interoperable and far more on the horizon, such as blockchain and technologies to not just meet demands for more bandwidth but also to power connected devices.

On the technological front it’s important to look at the technologies underneath terms such as IoT but also to look at how it all connects, especially as on this technology level (where data and how you leverage, protect, exchange, enrich and even monetize it is at the center as you can see in the above list) the keyword is integration as well: from the integration of IT and OT to the integration of IoT and AI; big data, IoT and AI; blockchain and IoT.

This more or less summarizes the key aspects, elements and evolutions in Industry 4.0 for professionals. In the rest of this page we look deeper at the mentioned elements and more. Some are in the guide itself, others are added and for the time being linked to.

Origins and history of Industry 4.0

Although Industry 4.0 originally was mainly used for manufacturing (in contrast with other initiatives that were taking place such as the Industrial Internet with the Industrial Internet Consortium or IIC), it is de facto going further.

The economy is on the verge of the fourth industrial revolution. Driven by the Internet, real and virtual world continue to converge towards an Internet of Things (Die neue Hightech-Strategie Innovationen für Deutschland)

Several parties that were involved in Industry 4.0 themselves move it to smart transportation and logistics, smart buildings, smart mining, smart oil and gas, smart healthcare, and smart ‘x’ or ‘anything’. Remember that in the Industrie 4.0 view, smart products make us shift from centralized control systems to an approach whereby smart products define production process steps. The smart ‘x’ is at a higher level. Yet, let’s take a look at how we got there and the origins/history of Industrie 4.0.

The start: Industrie 4.0 and Germany’s High-Tech Strategy reorientation

In 2006, the German government presented its “High-Tech Strategy” at Hannover Messe.

In ‘Die Neue Hightech-Strategie Innovationen für Deutschland’, the government explained how it aimed to drive innovation, which wasn’t just a matter of technological innovation but also about ‘social innovation’ with society overall put at the center, a bit like Japan’s Society 5.0.

The strategic reorientation, which, among others, would drive R&D priorities and involved several departments, included five core elements. One of them was the definition of priorities in regards to future tasks to create value and (enhance) quality of life with one such future task being ‘digital economy and society.’

It’s here that Industrie 4.0 was first mentioned in a clear relationship with the advent of a fourth industrial revolution, driven by the Internet and the Internet of Things. The document described the characteristics of the industrial production of the future as follows:

- A high degree of individualization (personalization) of products with a highly flexible production;

- The early inclusion/involvement of customers and business partners in design and value creation processes;

- Connecting production and high-quality services which would lead to so-called hybrid products.

The government expressed its intention to support the business and science community to develop and implement Industrie 4.0 with additional focus on security and the impact on labor and employment. Other digital priorities included smart services, smart data, cloud computing, digital/intelligent networking, digital science, digital education and digital living environments. Most are closely tied to Industrie 4.0.

To examine the priorities of the high-tech strategy and come up with innovation recommendations, a working advisory group for innovation policy was created. Dr. Henning Kagermann of the German National Academy of Science and Engineering (acatech) and previously at SAP, was appointed as the lead.

The future project Industrie 4.0

Five years later, in 2011, Dr. Kagermann, Dr. Wolfgang Wahlster of the German Research Center for Artificial Intelligence (DFKI) and Dr. Wolf-Dieter Lukas from the Federal Ministry of Research and Education presented the results of the work of the advisory group across various domains, including Industrie 4.0, which from then on became broadly known.

The business potential of the 4th industrial revolution lies not only in operational process optimization, but also in its services for a wide range of applications. The Internet of Things is therefore complemented by the so-called “Internet of Services”, because smart products offer their capabilities as intelligent services (Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. industriellen Revolution, 2011)

Before the presentation in the form of a press conference at Hannover Messe, they published an article (PDF opens), entitled “Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. industriellen Revolution” (Industry 4.0: on the road to the fourth industrial revolution with the Internet of Things).

The future project Industrie 4.0 was adopted and revolved around the creation of new business models thanks to cyber-physical systems. To further develop it, Plattform Industrie 4.0 was created in 2013 by Bitkom (Germany’s digital association), VDMA (German Mechanical Engineering Industry Association), and ZVEI (Germany’s Electrical Industry), later joined by others.

Along with these other partners, including acatech, they still work on Industry 4.0, among others on the level of standardization and international collaboration, gauging progress of Industry 4.0, education and R&D. Yet, Industry 4.0 is not just an industrial policy issue. It also addresses ecological and social challenges such as resource efficiency, environmental protection or urbanization.

Plattform Industrie 4.0 today still works on several of the mentioned tasks and challenges ahead to make Industry 4.0 a reality through its working groups, on levels such as standards, norms, reference architectures, security, applications, business models, legal aspects (also data-related), work, education and skills, global collaboration, etc. Given the internationalization of Industry 4.0, Plattform Industrie 4.0 also has an English website since several years, albeit still with a strong German emphasis.

This global diffusion of the Industrie 4.0 vision and technologies, at different speeds, is related with the universal challenges and possibilities across the globe and with the cross-fertilizations, enabled by collaborations with the US industry, the Japanese industry, EU industry initiatives and so forth. Still, there are several hurdles to take before the Industry 4.0 vision is realized in more companies than is the case today.

Industry 4.0 definitions – what is Industry 4.0?

The initial goals in Industry 4.0 typically are automation, (manufacturing) process improvement and productivity/production optimization; the more mature goals are innovation and the transition to new business models and revenue sources with information and services as cornerstones. Let’s look at some Industry 4.0 definitions.

The original definition of Industry 4.0

The definition of Industrie 4.0 as proposed in 2011 was pretty lengthy. In a paper, entitled “Industrie 4.0 – Smart Manufacturing for the Future”, GTAI (Germany Trade and Invest) looked at the questions what is smart industry (a synonym of Industry 4.0) and what Industrie 4.0 means.

An extract: Smart industry or “INDUSTRIE 4.0” refers to the technological evolution from embedded systems to cyber-physical systems…INDUSTRIE 4.0 represents the coming fourth industrial revolution on the way to an Internet of Things, Data and Services. Decentralized intelligence helps create intelligent object networking and independent process management, with the interaction of the real and virtual worlds representing a crucial new aspect of the manufacturing and production process”.

And it’s not done! More in the paper (PDF opens) and in our Industry 4.0 definitions list below.

More Industry 4.0 definitions

Obviously not all definitions of Industry 4.0 are the same. Industry 4.0 in practice means many things for many people and what some consider a definition of Industry 4.0, others won’t.

Industry 4.0 has been defined as “a name for the current trend of automation and data exchange in manufacturing technologies, including cyber-physical systems, the Internet of things, cloud computing and cognitive computing and creating the smart factory”.

The Working Group that developed the concept of Industry 4.0 regards it as a series of disruptive innovations in production and leaps in industrial processes resulting in significantly higher productivity. It is viewed as the fourth time such a disruption took place. (German Federal Ministry of Education and Research, Project of the Future: Industry 4.0)

This Industry 4.0 definition is close to the original definition but not entirely correct or at the very least not correct anymore as Industry 4.0 goes beyond the factory, is also about more than automation and data exchange (e.g. the key role of workers, the key role of energy efficiency etc).

If we take the above-mentioned German Plattform Industrie 4.0 as the official reference for all things Industry 4.0, an official definition, per the platform, goes as follows: “Industrie 4.0 refers to the intelligent networking of machines and processes for industry with the help of information and communication technology”.

Industry 4.0 and the fourth industrial revolution (4IR)

As a reminder the classic view of these four industrial revolutions, as Industry 4.0 became increasingly popular, was:

- The first industrial revolution, which REALLY was a revolution, and, among others thanks to invention of steam machines, the usage of water and steam power and all sorts of other machines, would lead to the industrial transformation of society with trains, mechanization of manufacturing and loads of smog.

- The second industrial revolution is typically seen as the period where electricity and new manufacturing ‘inventions’ which it enabled, such as the assembly line, led to the area of mass production and to some extent to automation.

- In the fourth industrial revolution we move from ‘just’ the Internet and the client-server model to ubiquitous mobility, the bridging of digital and physical environments (in manufacturing referred to as Cyber Physical Systems), the convergence of IT and OT, and all the previously mentioned technologies (Internet of Things, Big Data, cloud, etc.) with additional accelerators such as advanced robotics and AI/cognitive which enable Industry 4.0 with automation and optimization in entirely new ways that lead to ample opportunities to innovate and truly fully automate and bring the industry to the next level.

Some also like to add the injection of technology and connectivity in the human/digital mind and body convergence to Industry 4.0.

The injection of AI, hyper-connectedness and data analysis into how things, machines, communicate, act and lead to actionable insights with an omnipresence of the Internet of Everything in virtually each piece/machine of the Industry 4.0 dream is one thing, the convergence of man and machine (or technological extension) is still a bit further away and it’s so complex and will lead to so many more debates (also ethical) that it’s already called the fourth platform by IDC.

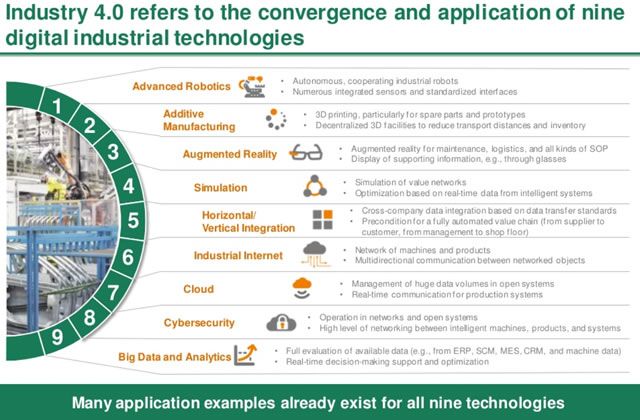

In the view of the Boston Consulting Group (we tackle their Industry 4.0 research below) Industry 4.0 refers to the convergence and application of nine digital industrial technologies: advanced robotics, additive manufacturing, augmented reality, simulation, horizontal/vertical integration, Industrial Internet, the cloud, cybersecurity and Big Data and Analytics.

It’s clear that today some companies have invested in a few of these technologies; predominantly the traditional pillars of the third platform such as cloud and Big Data / Analytics and, increasingly in the Industrial Internet of Things from an integrated perspective and thus overlapping with several of these “technologies” or maybe better: sets of technologies and connected benefits.

Industry 4.0 and the Industrial Internet

Obviously, it wasn’t just in Germany (and Europe) that the digital transformation of manufacturing (and some related industries and processes) was occurring with industrial giants in the Industry 4.0 space (Bosch, Siemens, you name it).

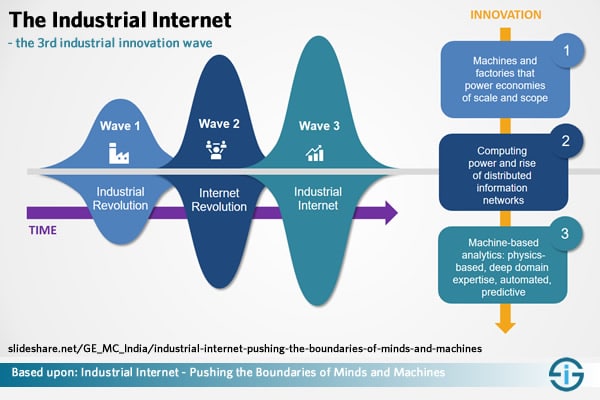

The fourth Industrial Revolution and the third industrial innovation wave of the Industrial Internet

As mentioned, in the US, GE and a range of other industrial players (including non-American ones who are also members of the “Plattform Industrie 4.0”) launched the Industrial Internet Consortium.

The Industrial Internet, as we wrote previously a term coined by American industrial giant GE, looked pretty much like Industry 4.0., although in the Boston Consulting Group image above it is mentioned as one of the enabling industrial technologies in the network of machines and products and networked objects communications sphere of IIoT.

The difference between Industry 4.0 and the Industrial Internet, however, is that, originally, the Industrial Internet was seen as the third industrial innovation wave. So, a third wave of innovation instead of a fourth revolution in the industry.

It only shows how relative revolutionary terms are as the three industrial Internet innovation waves respectively were:

- The Industrial Revolution. The real one and more or less a combination of the first and second revolution in the Industry 4.0 view.

- The Internet Revolution: ‘computing power and the rise of distributed information networks’.

- The Industrial Internet: what is called the fourth industrial revolution in Industry 4.0.

Today the concept of four industrial revolutions, however, has gained widespread adoption and so has Industry 4.0.

Globalization, architectures and standardization: the collaboration between Industry 4.0 and the Industrial Internet Consortium

The Industrial Internet Consortium had a more cross-industry approach than German “Plattform Industrie 4.0” (the Industry 4.0 Platform), which was more focused on manufacturing (although it’s also used for logistics and more).

As both the Industrial Internet Consortium and Plattform Industrie 4.0 shared many efforts and views, and more and more companies became member of both platforms, both organizations started looking at similarities and collaboration. After all, we still do live in a globalized world, certainly in industrial production and related markets.

So, collaboration became obvious, even more so because both industry bodies were working on an architectural framework. In the context of Industry 4.0 and “Plattform Industrie 4.0” this framework is known as RAMI 4.0, short for the Reference Architecture Model for Industrie 4.0. The Industrial Internet Consortium’s framework is known as IIRA, short for the Industrial Internet Reference Architecture.

Early 2016 the Industrial Internet Consortium and Plattform Industrie 4.0 announced their collaboration, with a focus on standardization, the architecture for the “new” manufacturing, the business goals and the role of the Internet of Things in it all.

If you look at Industry 4.0 today you’ll notice that there is also an increasing attention for industries, other than manufacturing as already was the case in the Industrial Internet Consortium and that cyber-physical systems, which we’ll tackle next are seen beyond the scope of cyber-physical production systems but also as the enablers of, among others condition monitoring and remote possibilities, which in term don’t just enable and drive the smart factory.

The state of Industry 4.0

All revolutions and associations aside, the question is how far we are in Industry 4.0. Are manufacturing companies fully ready? And what means readiness in this industrial context to begin with?

In other words: what are the characteristics, principles, technological maturity levels, (achieved and desired) benefits and realizations and where do we start with Industry 4.0 or the Industrial Internet? As you’ll notice the answers to these questions are very similar to those in digital transformation across any industry and as in any digital transformation strategy challenge. After all; in the end, regardless of the different technologies and market context in manufacturing, digital transformation is a universal given in any industry whereby similar capabilities and outcomes are sought. Yet, as mentioned in the beginning of this article, Industry 4.0 is a vision and reality with projects and clear steps towards the vision.

Industry 4.0, which in more than one way as said is the digital transformation of manufacturing, today still is mainly focused on the first stages of transformation and ‘maturity’ from a benefit and potential perspective: enhancing productivity, automation and the optimization of operational processes, business processes and, the number one Internet of Things use case from an IoT spending perspective: manufacturing operations, followed by (predictive) maintenance and smart maintenance services.

Industry 4.0 and the first stages of maturity

This is also what the Boston Consulting Group found in a December 2016 report: companies are implementing Industry 4.0 but in rather ad hoc and isolated ways.

This is exactly the same phenomenon we see in any industry that is in digital transformation – or revolution if you prefer. It’s that first stage in a broader ecosystem of possibilities as organizations move from more or less obvious goals to true innovation and even disruption. The illustration below from the Boston Consulting Group shows some aspects of this broader ecosystem of possibilities, beyond the enhance productivity dimension.

In other words: MOST manufacturing and industrial companies (there are plenty of exceptions and we mention several across this site) are still in that stage where the intention to transform exists and isolated efforts exist but there is often a lack of a bigger picture, a broader strategy or, as the Boston Consulting Group calls it in the Industry 4.0 context ‘a comprehensive program’.

Industry 4.0 ranks high on the agenda, yet in practice one or two isolated aspects of Industry 4.0 are implemented, the company says. Examples: big data and/or robotics.

This is really the first stage of maturity whereby there is also a focus on the mentioned optimization and automation goals and gains, which is perfectly normal but it shouldn’t stop there.

You can perfectly compare this with the findings of IDC regarding the gradual evolution from Internet of Things pilot projects to more scalable deployments, whereby IDC found that the sought benefits of these deployments are mainly focused on internal goals and on operations.

This situation is poised to remain like that for a while tough as, despite the increasing number of large IoT projects, the Internet of Things is more seen as strategic and tactical than transformational and internal goals are key.

Industry 4.0 – the next maturity stages

Where the Boston Consulting Groups says that the vast majority of respondents see Industry 4.0 as an opportunity to improve productivity – and analyzes how this is done in practice- the parallels are crystal clear. So, what does it take to move to those next maturity stages?

Industry 4.0 is the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of things and cloud computing. Industry 4.0 creates what has been called a “smart factory”.

Not for the sake of maturity but for the sake of moving beyond that enhanced productivity towards higher agility, real-time opportunities, the development of an innovative capability and true innovation, identifying new information-driven and service-oriented sources of revenue and many more goals?

The answers are again the same as in all digital transformations, as are the challenges. Developing new competencies, finding new opportunities in the equation of intelligence, people, processes and innovation, and creating competitive benefits and services which can have an important impact on the business model and even the industry as a whole, requires more than projects and more than productivity.

In practice, even ten years after the “launch” of Industrie 4.0 we see that most enterprises are still in the quite early stages of their cyber-physical convergence efforts per at least one analyst.

Industry 4.0 challenges and risks

And it’s here that also in Industry 4.0 we find those eternal hurdles. The Boston Consulting Group, among others, identified:

- The definition of a strategy (for Industry 4.0), challenge number one.

- The rethinking of the organization and processes to maximize outcomes.

- Understanding the business case.

- Conducting successful pilots.

- Making the organization realize action is needed.

- Change management, so often overlooked.

- Company culture.

- A true interconnection of departments.

- Talent….

They are all challenges we’ve seen in so many other areas and there are at least two we want to add (there are more):

- Information management excellence as it’s all about actionable intelligence and connected information and process excellence in a context of relevance, innovation and timely availability for any desired business, employee AND obviously customer goal.

- (Cyber)security (and privacy). The increasing number of attacks in the Industrial Internet of Things are a fact as IT and OT converge. Moreover, one of the main reasons which hold IIoT initiatives back are concerns regarding security and IIoT is, as said a key component of Industry 4.0.

On top of these challenges there are several others, practical, technological and ecosystem-related:

- The challenges regarding the integration of IT and OT.

- Data compliance questions.

- Managing risk and lowering costs in uncertain times.

- Dealing with the complexity of the connected supply chain.

- A better understanding of IT and OT technologies and, more importantly, how they can be leveraged.

- Altering customer and industrial partner demands.

- Competition and the fact that Industry 4.0 champions gain a competitive benefit fast.

- The eternal and extremely important human challenge (talent, future of work, employment,…..).

While leading manufacturers are overcoming the mentioned challenges and some already have, others will need to step up their pace. It’s not a coincidence that the Boston Consulting Group report is entitled ‘Sprinting to Value in Industry 4.0’.

Is fear of others taking the lead a good advisor? No? Do you need to start somewhere? Yes, and you can. Is it, even if fear is a bad advisor, time to sprint to value in Industry 4.0 in a world where digital transformation is a marathon with several sprints? Looking at what the best in class are doing we would say yes.

Benefits of Industry 4.0

Whether it’s Industry 4.0, Smart Industry or the Industrial Internet, there are ample benefits for manufacturers to transform the way they work.

We’ve mentioned some benefits, risks and challenges earlier in this overview but let’s look a bit closer at some of the main advantages. Several of them are also explored more in depth in other articles on this site.

The essential goal of Industry 4.0 is to make manufacturing – and related industries such as logistics – faster, more efficient and more customer-centric, while at the same time going beyond automation and optimization and detect new business opportunities and models.

Most of the benefits of Industry 4.0 are – obviously – similar to the benefits of the digital transformation of manufacturing, the usage of the IoT in manufacturing, operational and business process optimization, information-powered ecosystems of value, digital transformation overall, the Industrial Internet and many other topics on our website. However, let’s summarize a few of the key benefits of Industry 4.0.

Enhanced productivity through optimization and automation

As mentioned in the section on the state of Industry 4.0, optimization of processes and of productivity is the first benefit that manufacturers see.

It’s also one of the first goals of Industry 4.0 projects. In other words: saving costs, increasing profitability, reducing waste, automating to prevent errors and delays, speeding up production to work more in real-time and in function of the overall value chain, where speed is crucial for everyone, digitizing paper-based flows, being able to intervene faster in case of production issues and so forth.

It’s the low hanging fruit, yet important. On top of the research from BCG we mentioned earlier, the signs that investments are done in these areas first are clear. Again, it’s not a coincidence that, from a spending perspective, the number one use case in which manufacturers invest their Internet of Things (IoT) budgets is manufacturing operations (a whopping $102.5 billion on a total of IoT $178 billion across all manufacturing use cases in 2016). Industry 4.0 offers various solutions to optimize, from optimized asset utilization and smoother production processes to better logistics and inventory management.

Real-time data for a real-time supply chain in a real-time economy

While we just mentioned speed in a context of optimization, automation and enhanced productivity, it is a benefit in many other ways as well.

A lot of the productivity improvement benefits are rather about the internal goals of costs and process optimization. Yet, at the same time several also fit in a perspective of enhanced customer-centricity.

Industry 4.0 is about the entire life cycle of products and manufacturing obviously doesn’t stand on its own. If you look at the entire value chain and ecosystem within which manufacturing operations reside there are many stakeholders involved. These are all customers. And customers also want enhanced productivity, regardless of where they sit in the supply chain. If the final customer wants good products fast and has increased expectations regarding customer experience, quality (hence the importance of ‘Quality 4.0’, TQM with an Industry 4.0 flavor), service and products that are delivered on the exact time they want, this impacts the whole supply chain, all the way up to manufacturing and beyond.

Speed is not just a competitive advantage and customer expectation in an increasingly real-time economy, it’s also a matter of alignment, costs and value creation. Moreover, customers simply expect it.

Once again the crucial role of data and information surfaces.

Industry 4.0, smart factories, supply chains, informed customers, alignment: it’s all about data, from the actual operations to the delivery of a product to an end customer and beyond.

The more data you gather early on and the more timely this data gets where it matters when it matters, the more value down the supply chain. In fact, this is the essence of one of the three dimensions of RAMI 4.0, the Reference Architecture Model Industry 4.0, which we tackle below.

Higher business continuity through advanced maintenance and monitoring possibilities

When an industrial asset gets broken it needs to be fixed. That costs time, money and very often a lot of moving around by support people and engineers.

When a key industrial asset, such as an industrial robot in a car manufacturing plant gives up, it’s not just the robot that’s broken. Production is affected, costing loads of money and unhappy customers, and sometimes production can be fully disrupted. It’s everyone’s worst nightmare as business continuity is an extremely high concern.

On top of all the replacement/fixing work, resources and costs, reputation can be damaged, orders can be cancelled and with each hour that passes money is thrown away. If industrial assets are connected and can be monitored (health status monitoring, for instance) through the Internet of Things and issues are tackled before they even happen the benefits are huge. Alerts can be set up, assets can be proactively maintained, real-time monitoring and diagnosis becomes possible, engineers can fix issues, if they do occur from a distance, the list goes on. Moreover, patterns and insights are gained to optimize in areas where things seem to have issues more often and a world of new maintenance services opens up as we’ll see. No wonder that asset management and maintenance are the second largest area of IoT investments in manufacturing.

Better quality products: real-time monitoring, IoT-enabled quality improvement and cobots

We mentioned that customers want speed. However, that doesn’t mean they are ready trade quality for speed, well on the contrary.

If you have everything in your production system and its broader environment hooked up with smart sensors, software, IoT technologies, systems of insight AND the customer, you can also enhance quality of your products. Automation definitely plays a big role here and so do the typical components of cyber-physical systems (more below) and the Internet of Things whereby quality aspects can be monitored in real-time and robots reduce errors.

On the flip side and one of the risks and challenges to tackle, as mentioned earlier: the more you automate, the less work for people, in theory. And the same goes for other mentioned benefits such as maintenance (the less you need engineers for support, the less support engineers you need). It’s a dilemma and known issue which we’ll cover later. In the meantime do know that robots are not going to take all human jobs over soon. Ample companies have increased the usage of robots and at the same time hired more. The reason we mention it in the context of quality is that this is certainly one area where you see cobots popping up (cobots is a fancy term for advanced collaborative robots or put more simply: robots that fit a collaboration between man and machine).

Better working conditions and sustainability

Talking about people, the human (and social) dimension is ubiquitous in Industry 4.0. Moreover, if we look at the possibilities and benefits, that human, social and even sustainability aspect is key in the goals of Industry 4.0.

Improving working conditions based on real-time temperature, humidity and other data in the plant or warehouse, quick detection and enhanced protection in case of incidents, detection of presence of gasses, radiation and so forth, better communication and collaboration possibilities, a focus on ergonomics, clean air and clean factory initiatives (certainly in Industry 4.0 as the EU wants to be leading in clean air and clean anything technologies), the list goes on. Moreover, the whole notion of Electricity 4.0 and of a sustainable industry for an All Electric Society is becoming ever more important.

Personalization and customization for the ‘new’ consumer

We all know it: consumer behavior and preferences have changed. Digital tools have changed the ways we work, shop and live.

People have also become more demanding, among others with regards to fast responses and timely information/deliveries as mentioned earlier. On top of that consumers also like a degree of personalization, depending on the context. Take sports shoes, for instance. Once a few colors of the same shoe were enough, know we want the ability to customize them in whatever way.

On top of that another phenomenon is taking place and it does disrupt traditional supply chains. Consumers increasingly get (and want) possibilities to have a direct interaction with a brand and its manufacturing capability. Digital platforms to customize products as mentioned, shortened routes between production and delivery, possibilities to co-create and so on. In many manufacturing environments these things already happen. And it’s not just in a consumer environment. We increasingly see customization in a B2B context as well, even if it’s just to stick a label, add a custom feature or adapt any characteristic of the product whatsoever.

If you want to offer these services at scale and even turn them into a competitive advantage, automation and several technologies and processes in industry 4.0 become a necessity. A real-life example without disclosing the details: a large bank wanting specific office equipment to use across all its branches (customer-facing context) with its own look, feel and features as part of a rebranding. There are plenty more examples.

Improved agility

Now that we speak about competitive benefits and customization we also need to tackle agility, scalability and flexibility.

The same scalability and agility which we expect from supporting IT services and technologies, such as the cloud, are expected in manufacturing. This is partially related with the previous topic of customization but mainly is about leveraging technologies, Big Data, AI, robots and cyber-physical systems to predict and meet seasonal demand, fluctuations in production, the possibility to downscale or upscale; in other words: all the adjustments that are sometimes more or less predictable, can be made more predictable or are not predictable but can be handled thanks to increased visibility, flexibility and a possibility to leverage assets in function of optimal production requirements from a perspective of time and scale.

The development of innovative capabilities and new revenue models

Digital transformation, as you can read in our digital transformation strategy overview, is a matter of many levels, steps and capabilities.

You can transform processes, specific functions, customer service, experiences and skillsets but in the end true value is generated by tapping into new, often information-intensive, revenue sources and ecosystems, enabling innovative capabilities, for instance in deploying an as-a-service-capacity for customers, advanced maintenance services and so on.

In the end, Industry 4.0 is also about that. It’s a topic we wrote about very often. You can read more about it in our article on the digital transformation of manufacturing.

Industry 4.0 strategy and implementation

As mentioned previously, it’s important to point out that Industry 4.0 is still mainly a vision. Does this mean it is just a vague idea? No, on the contrary.

What we do see indeed though is that most organizations are still in the early stages of preparations for Industry 4.0 and mainly working ad hoc for now. Yet, the vision of Industry 4.0 is far more studied and documented that that of other evolutions.

Industrie 4.0 is a vision AND a reality with a documented strategic roadmap towards realizing the vision

Let’s compare digital transformation and the role in it of the Industrial Internet of Thing, which along with evolutions in mechanics, engineering and manufacturing, essentially are what Industry 4.0 is about.

Businesses with comprehensive Industry 4.0 strategies believe they are far more successful across multiple dimensions, including measures related to financial performance, societal impact, talent, and technology investment (Deloitte)

Digital transformation, although being academically looked upon and despite the existence of numerous digital transformation frameworks and roadmap strategies, which are developed by numerous people, has no universal definition nor clear industry-wide approach. The same goes for the implementation of the Industrial Internet of Things.

Just like digital transformation and the Industrial Internet of Things, adoption of Industrie 4.0 happens in the individual context of an organization. However, Industry 4.0, which is about more than automation in manufacturing and ultimately also shows a vision of transformation in the end, is thoroughly studied, prepared and presented by a big platform with academia, companies and far more as it was a clear mandate.

In essence this means that in Industry 4.0 there is a body of work, reference models, roadmaps and well-described components before the actual implementations really happened. That is pretty unique.

So, just like digital transformation, Industry 4.0 requires a staged approach whereby the initiatives in the earliest maturity stages and areas ultimately lead to the realization of an integrated vision and reality. Yet, as opposed to digital transformation this vision and reality is far more studied, documented and standardized (despite the mentioned need to work in the context of the individual business as well).

Industry 4.0 maturity models and roadmap basics

In the Industry 4.0 maturity models there are several ways to look at the mentioned staged approaches. One such maturity approach looks at the information and actual operations and manufacturing systems perspective with autonomous machines and systems as true Industry 4.0.

In this gradual approach, whereby each stage builds upon the next one and adds more value, we move from data to information to knowledge to wisdom and action from a data perspective. Indeed, the good old DIKW model.

From the perspective of systems and equipment/machines these stages correspond with, respectively seeing what is happening (data), knowing why it’s happening (analytics, knowledge), predicting what will happen (based upon the patterns and capabilities we developed before and AI) to the ultimate step Industry 4.0 strives for: an autonomous reaction by autonomous machines within the self-optimizing Industry 4.0 systems.

A second maturity approach revolves more around the business as such and corresponds with what you would typically see in any project.

What do we want to achieve and what do we have today (assess), where do we want to go and what are the missing links to get there (called the methodological analysis in Industrie 4.0, of which gap analyis is part) and then the deployment of a strategic plan with a clear roadmap with regards to processes, security, skills, technologies and implementation.

And, as is always the case this is of course followed by monitoring and improvement.

The Industry 4.0 holistic strategy challenge

While some organizations have more or less consistent and holistic strategies with regards to Industry 4.0, most do not. A lack of strategy proves to be one of the major challenges as it does in so many business areas.

There is a big gap between those companies that have a long-term strategy and the rest. On the other hand, it needs to be said that those so-called ‘lighthouses’ are often active in the industry. The truth is that most organizations don’t have an Industry 4.0 strategy and also suffer from strategic short-termism. This isn’t even that surprising since, as some brand strategists have been shouting for quite some years now organizations overall are focusing far too much on the short term for reasons that are partially related to the Zeitgeist and our real-time here and now obsessions. Changing demands play a role as well as do financial and competitive reasons.

Anyway, in the scope of Industry 4.0, it’s clear that ad hoc and siloed initiatives, by far the large majority of initiatives, won’t cut it unless they’re part of a strategic journey. And quite often they are not, leading to fewer results than hoped or even failure.

In a 2020 Industry 4.0 report from Deloitte, the focus on the short term and lack of a holistic strategy again became clear.

The fast pace of disruption in Industry 4.0 makes it critical for organizations to maintain holistic, integrated strategies and seek long-term growth opportunities, Deloitte says. However, the survey suggests leaders have a long way to go. Two-thirds said they have no formal strategy to address Industry 4.0, and only 10 percent overall said they have comprehensive strategies that integrate a focus on Industry 4.0 throughout their organizations.

Cyber-physical systems: the building blocks of Industry 4.0

Cyber-physical systems (CPS) are building blocks in Industry 4.0 on one hand and part of the Industry 4.0 vision on the other.

Cyber-physical systems are combinations of intelligent physical components, objects and systems with embedded computing and storage possibilities, which get connected through networks and are the enablers of the smart factory concept of Industry 4.0 in an Internet of Things, Data and Services scope, with a focus on processes.

Simply put, as the term indicates, cyber-physical systems refers to the bridging of digital (cyber) and physical in an industrial context.

Cyber-physical systems (CPS) in the Industry 4.0 vision

This might still seem complex but, then again, cyber-physical systems are complex. Moreover, the term isn’t new and is better known in an engineering and industry context.

It fits more in the Operational Technology (OT) side of the converging IT/OT world which is typical in Industry 4.0 and the Industrial Internet. So, if you want to understand Industry 4.0 or the Industrial Internet, you’ll need an understanding of some essential operational, production and mechanics terms.

Cyber-physical systems in the Industry 4.0 view are based on the latest control systems, embedded software systems and also an IP address (the link with the Internet of Things becomes clearer, although strictly both are not the same but they certainly are twins as we see in the next ‘chapter’.

In the Industry 4.0 context of mechanics, engineering and so forth, cyber-physical systems are seen as a next stage in an evolution of an ongoing improvement of enhancement and functions integration.

Looking at Industry 4.0 as the next new stage in the organization and control of the value chain across the lifecycle of products, this ongoing improvement in which CPS fits started from mechanical systems, moved to mechatronics (where we use controllers, sensors and actuators, more terms that are familiar in IoT) and adaptronics, and is now entering this stage of the rise of cyber-physical systems.

Cyber-physical systems essentially enable us to make industrial systems capable to communicate and network them, which then adds to existing manufacturing possibilities.

They result to new possibilities in areas such as structural health monitoring, track and trace, remote diagnosis, remote services, remote control, condition monitoring, systems health monitoring and so forth.

And it’s with these possibilities, enabled by networked and communicating cyber-physical modules and systems, that realities such as the connected or smart factory, smart health, smart cities, smart logistics etc. are possible as mentioned previously.

Cyber-physical systems before Industry 4.0

In the original definitions, going back over a decade, IP addresses where not specifically mentioned in cyber-physical systems.

In 2008, Professor Edward A. Lee from the University of California, Berkeley, defined Cyber-Physical Systems as follows: “Cyber-Physical Systems (CPS) are integrations of computation and physical processes. Embedded computers and networks monitor and control the physical processes, usually with feedback loops where physical processes affect computations and vice versa”.

On his page on the Berkeley website, Professor Lee links to cyberphysicalsystems.org where you find his definition and a CPS concept map in the form of a mind map where you can click the various components to read more. For the German Industrie 4.0 academia and industry people, CPS (and that bridging of cyber/digital and physical) was key in Industry 4.0.

Cyber-physical systems also include dimensions of simulation and twin models, smart analytics, self-awareness (self-configuration) and more . We’ve tackled some of these topics, including digital twins, previously.

Hopefully, the essence of the concept, context and reality of the evolution towards cyber-physical systems has become a bit clearer now. Note: there is a difference between cyber-physical systems and cyber-physical manufacturing systems or cyber-physical production systems (CPSS) where we move from the technological component to the far more important process and application dimension.

Cyber-physical systems: summary of the key characteristics

Next, we take a deeper look into the Internet of Things and its place in Industry 4.0. You’ll notice that both are virtually twins.

Before doing so we summarize some key characteristics of cyber-physical systems as they are related with the Internet of Things:

- Cyber-physical systems are seen as a next evolution in manufacturing, mechanics and engineering. The essential dimensions are the bridging of digital and physical, which is possibly thanks to Internet technology, and the bridging/convergence of Information Technology and Operational Technology.

- Cyber-physical systems can communicate. They have intelligent control systems, embedded software and communication capabilities as they can be connected in a network of cyber-physical systems.

- Cyber-physical systems can be uniquely identified. They dispose of an IP (Internet Protocol) address which means that they use Internet technology and are part of an Internet of Everything in which they can be uniquely addressed (each system has an identifier).

- Cyber-physical systems have controllers, sensors and actuators. This was already the case in previous stages before cyber-physical systems (mechatronics and adaptronics); however as we’ll see with the Internet of Things it plays an important role.

- Cyber-physical systems are the basic building blocks of Industry 4.0 and the enablers of additional capabilities in manufacturing (and beyond) such as track and trace and remote control (more about these capabilities in the next section on CPS and the Internet of Things).

- The capabilities which are possibly thanks to cyber-physical systems enable smart factories, smart logistics (Logistics 4.0) and other smart areas of applications, among others in energy, oil and gas, and utilities.

Industry 4.0 building blocks: the (Industrial) Internet of Things

As promised, time for the Internet of Things. The Internet of Things (IoT) is omnipresent in Industry 4.0 and its international counterparts, as mentioned previously.

As you can read on our page on the Industrial Internet of Things (IIoT) and deduct from the graphic above on cyber-physical systems, CPS essentially is mainly about the Industrial Internet of Things.

Internet of Things and cyber-physical systems: similar characteristics

The presence of an IP address by definition means that cyber-physical systems, as objects, are connected to the Internet (of Things). An IP address also means that the cyber-physical system can be uniquely identified within the network. This is a key characteristic of the Internet of Things as well.

Cyber-physical systems are also equipped with sensors, actuators and all the other elements which are part of the Internet of Things. Cyber-physical systems, just like the Internet of Things need connectivity. The exact connectivity technologies which are needed depend on the context (in both).

The Internet of Things consists of objects with embedded or attached technologies that enable them to sense data, collect them and send them for a specific purpose. Depending on the object and goal this could be capturing data regarding movement, location, presence of gasses, temperature, ‘health’ conditions of devices, the list is endless. This data as such is just the beginning, the real value starts when analyzing and acting upon them, in the scope of the IoT project goal.

IoT devices can also receive data and instructions, again depending on the ‘use case’. All this applies to cyber-physical systems as well, which are essentially connected objects. There are more similar characteristics but you see how much there is in common already.

CPS-enabled capabilities and Internet of Things use cases

Moreover, the new capabilities which are enabled by cyber-physical systems, such as structural health monitoring, track and trace and so forth are essentially what we call Internet of Things use cases.

In other words: what you can do with the Internet of Things. Some of them are used in a cross-industry way, beyond manufacturing.

Below are two examples of CPS-enabled capabilities we tackled previously and how they really are IoT uses cases.

Track and trace possibilities in practice lead to multiple IoT use cases in, among others, healthcare, logistics, warehousing, shipping, mining and even in consumer-oriented Internet of Things use cases. There are ample applications of the latter with numerous solutions and technologies. You can track and trace your skateboard, your pets, anything really, using IoT.

Structural health monitoring is also omnipresent, mainly across industries such as engineering, building maintenance, facility management, etc. With the right sensors and systems you can monitor the structural health of all kinds of objects, from bridges and objects in buildings to the production assets and cyber-physical assets in manufacturing and Industry 4.0.

Smart factories, smart plants and smart applications

The new capabilities, of which we just mentioned two and which are possible thanks to CPS in the Industry 4.0 view, in turn enable smart plants, smart factories and anything smart.

What is a core enabler of smart logistics and so forth? Indeed, the (Industrial) Internet of Things, beyond its simple aspects of sensors, actuators, communication capabilities and data collection/analytics. You can perfectly compare this with the Internet of Everything view of connected objects, people, processes and data as the building blocks of smart applications.

It is another key similarity between the CPS view of industry 4.0 and the reality of the Internet of Things, which is key in Industry 4.0.

To conclude: in fact, you can call cyber-physical systems the (albeit advanced) things in the Industrial Internet of Things in manufacturing. So, CPS and IoT are de facto more than twins.

Reference Architectural Model Industrie 4.0 (RAMI 4.0)

While, as mentioned the Industrial Internet Consortium has a framework, called IIRA (Industrial Internet Reference Architecture), German ‘Plattform Industrie 4.0’ developed the so-called Reference Architectural Model Industrie 4.0 (RAMI 4.0).

Industry 4.0 and RAMI 4.0: international expansion

RAMI 4.0, although originating from Germany, just as Industrie 4.0, is playing an increasing role in other countries as well. As a matter of fact, ‘Platfform Industrie 4.0’ is seeking alignment at European levels and with other countries across the globe.

Even if some EU countries use different terms such as intelligent factory, future industry, digital production or smart manufacturing, the European Commission (EC) is also intervening.

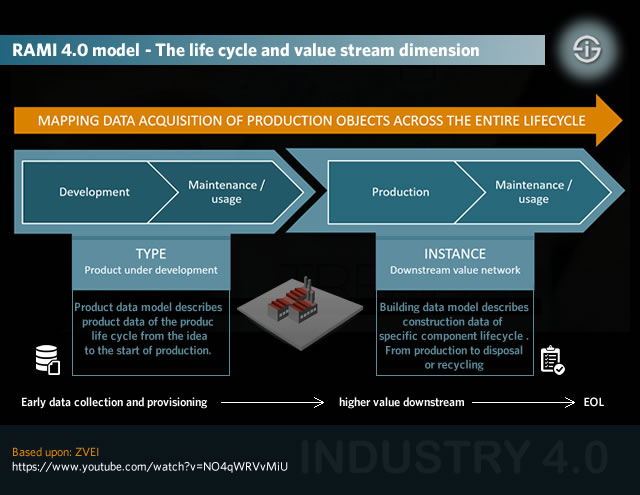

The 3-dimensional RAMI 4.0 model shows that the production object must be tracked across its entire life cycle

Early 2017, a forum was held in the scope of the EC’s ‘Digitizing European Industry’ project. Industry 4.0 and RAMI 4.0 are also clearly mentioned within various programs on the website of the EC (and a PDF with the essence of the Reference Architectural Model Industrie 4.0 is available on it, not without reason).

At the mentioned forum, the so-called ‘Stakeholder Forum’, held early 2017, international collaboration around Industry 4.0 was one of the topics. ‘Plattform Industrie 4.0’ used the occasion to further expand bilateral relationships with, among others the French Industry of the Future Alliance (Alliance Industrie du Futur) and Italy’s Intelligent Factory project (Fabbrica Intelligente). Outside of the EU, partners include the mentioned IIC (Industrial Internet Consortium) and Japan’s Robot Revolution Initiative (meanwhile, Japan announced its all-encompassing Society 5.0 initiative at the CeBIT 2017 tradeshow).

An overview of the ongoing acceptance and leverage of Industrie 4.0 technologies, concepts and principles, as mentioned previously, at the bottom of this page with over a dozen Industry 4.0 initiatives across the globe.

Key elements of RAMI 4.0 (and Industry 4.0 components)

What are some of the key aspects you need to know about RAMI 4.0 (the architectural model overviewis embedded below)?

First, know that there are two documents which laid out the foundations of Industry 4.0 and RAMI 4.0.

The Industrie 4.0 workgroup findings report

In 2013, the so-called “Umzetsungsempfehlungen” document was published. It’s essentially the report of the ‘Industrie 4.0’ workgroup that, among others covered principles and foundations, including:

- Horizontal integration across value-added networks.

- Vertical integration and networked/connected production systems

- The technologies for CPPS (cyber-physical production systems)

- The consistency of engineering across the entire value chain.

We mention these topics of that first document as we’ll tackle them more in depth.

The Industrie 4.0 strategic implementation document: where RAMI 4.0 comes in

The second document, the “Umsetzungsstrategie”, a document with the recommendations for the strategic translation and implementation of Industry 4.0, was published in 2015 and contains the RAMI 4.0 model, the Industry 4.0 components and a research roadmap for implementation.

It’s this document and more specifically, RAMI 4.0 AND the Industry 4.0 components which we tackle here.

The 3 dimensions of RAMI 4.0

The RAMI 4.0 architecture reference model is explained using 3 dimensions:

- The first dimension consists of the hierarchy levels.

- The second dimension covers the life cycle and value stream.

- The third and final dimension covers the so-called RAMI (architecture) layers.

The hierarchy level

The hierarchy dimension consists of 7 aggregation levels, being 1) the connected world, 2) the enterprise, 3) work centers, 4) stations (or machines), 5) control devices, 6) field devices (sensor and actuators) and 7) products.

Important to note: while traditionally these levels are seen as a “real hierarchy” and depicted as a pyramid, in Industry 4.0 they are more conceived and depicted as a mesh in a reality of ubiquitous connectivity of everything, including processes, devices, products, organizations, ecosystems and so forth. In the pyramid that shows Industry 3.0 there are only 6 levels with the enterprise at the top. While it’s true that the connected world is far more connected from a technology and business perspective, we must point out that there is such a thing as the extended enterprise with its ecosystems since long before anyone even talked about Industry 4.0.

The hierarchy dimension is what we covered several times in our articles on ubiquitous connectivity and digital transformation but in a different scope of hierarchy with smart products and smart factories as part of this connected world.

It also about technologies (where we similar decentralizations all across the board) (IT and especially OT) and about the ubiquitous interaction of participants across hierarchy levels, whereby the product is seen as part of the network.

The life cycle and value stream dimension

The life cycle and value stream dimension, as the term already describes, covers the various data mapping stages across relevant life cycles in RAMI 4.0 and across the entire value chain and the various processes (and stakeholders).

We’ll cover this more in depth later as it’s key in the data part, starting from the pre-production development product data model, starting at the idea and development (data on, among others, , all the way across further stages downstream, including actual production and the various processes until the production object is end of life and gets recycled or trashed). The idea: the more data early on, the more value later on.

The architectural layer

The third dimension, the architecture layers, consists of 6 components: business, functional, information(a), communication, integration and asset.

Essentially we’re talking about 1) the enterprise and its business processes, 2) the functions of assets, 3) the required data, 4) communication as access to information, 5) integration as, quote, ‘transition from real to digital world and 6) assets as physical things in the real world.

Bring all three dimensions together and, on top of a nice visual, you have a 3D service-oriented architecture.

Industrie 4.0 principles: horizontal and vertical integration

After this introduction to RAMI 4.0, which as mentioned was laid out in the 2015 document with recommendations for Industry 4.0 strategies and implementations, let’s take a look at some other so-called Industry 4.0 principles.

These were established in the 2013 report in which the Industrie 4.0 workgroups presented their findings on, among others those principles and foundations. Remember that, as mentioned and as we’ll cover more in depth, those recommendations, principles and so forth mainly were about manufacturing but that de facto Industry 4.0, its principles, vision and elements are going beyond manufacturing – and will continue to do so as Industry 4.0 moves from vision to reality in meeting the inevitable transformation of other industries as they are already taking place today.

Despite the fact that there is a difference between horizontal and vertical integration the goal is the same: ecosystem-wide data information between various systems and across all processes, using data transfer standards and creating the basis for an automated supply and value chain.

Horizontal integration in Industry 4.0

Horizontal integration refers to the integration of IT systems for and across the various production and business planning processes.

In-between these various processes there are flows of materials, energy and information. Moreover, they concern both the internal as external (partners, suppliers, customers but also other ecosystem members, from logistics to innovation) flows and stakeholders.

In other words: horizontal integration is about digitization across the full value and supply chain, whereby data exchanges and connected information systems take center stage. As you can imagine this is not a small task. For starters, within organizations there are still quite some disconnected IT systems. This is a challenge for all organizations, industrial or not. If you start looking at seamless integration and data exchange with suppliers, customers and other external stakeholders, the picture becomes even more complex.

Also keep in mind the life cycle and value stream dimension of RAMI 4.0 here where we talked about the importance of early data collection and provisioning.

Whether it concerns product data or information about the various mentioned and other processes across the horizontal value chain (so, the path from supplier and production to end customer and/or other stakeholders/partners), there is still quite some work to do in this regard.

Nevertheless, it is critical for Industry 4.0 and for business overall. The benefits and drivers for this need for horizontally connected information systems are pretty comparable to those we find in information management, as are the disadvantages if systems are not integrated.