One of the great promises and at the same time one of the main focus areas in Industry 4.0 is the bridging of digital/cyber/virtual and physical worlds, hence the focus on cyber-physical systems.

Apart from the fact that this isn’t just a technology issue (nor is the Industry 4.0 vision as such), from the technological perspective one immediately thinks about the Internet of Things. However, virtual reality (VR) and augmented reality (AR) are certainly as important.

Global spending in virtual and augmented reality is poised to double every year through 2021 (IDC)

Virtual reality and augmented reality are used in several sectors and contexts, from consumer applications to manufacturers. Yet, it’s in manufacturing that augmented reality offers great value in myriad applications, in combination with several other technologies as per usual.

The use of VR and AR in manufacturing and other industries for which the term Industry 4.0 gets used is not fiction. It happens as we speak and is poised to accelerate as the benefits become increasingly clear, offerings, hardware and applications mature and move to the next level and manufacturers increase their digital transformation efforts on the strategic and staged path towards the realization of Industry 4.0 and the digital transformation of manufacturing.

The many use cases of virtual and augmented reality in Industry 4.0

Virtual reality and augmented reality can play a role in the typical earlier stages where optimization and enhanced productivity (quantity, quality, speed, flexibility) are more important than later stages of innovation and genuine business transformation (which can of course be set out as Industry 4.0 goals at the start, more about that in ‘Finding the value in Industry 4.0‘).

Just think about how simulation models and the use of augmented reality can speed up the entire production chain, in combination with the right data, starting from the use of AR and VR in virtual design. Or about the use of augmented reality in maintenance. And then there is of course the possibility to put a virtual layer, based on the right data and information, on top of the ‘reality’ in all sorts of factory and industry environments, using devices such as AR/VR glasses/viewers. The latter is probably the best known illustration of how de facto virtual or cyber and physical meet.

Use cases include machining and production, education and collaboration, factory planning, assembly, security, testing and digital prototyping, to name a few. As we’ll see showcasing and immersive (key in AR/VR) experiences on the customer side are important as well. So, marketers should also pay attention, certainly in the manufacturing of products where showcasing technological manufacturing expertise strengthens the perception of the technological wealth of both company and product. So, no, it is not a coincidence if many use cases of AR/VR in manufacturing which get a lot of attention are in, for example, the automotive industry (and certainly the luxury car brands).

In operations, you can certainly also imagine how, with the proper equipment and solutions (from the worker’s perspective as well of course, have you seen those first headsets?) service people, factory staff and logistics staff can better perform their tasks if they have the information they need in front of their eyes and two of their main work instruments, on top of their brain, free: the left hand and the right hand. The result: smoother processes and flows.

Augmented reality in Industry 4.0 today: follow the value and key assets

AR and VR is far from omnipresent in all the mentioned and other use cases applications, even in high-tech industrial manufacturing.

In this stage virtual and augmented reality certainly aren’t mainstream and you most likely will find them in (product) design, in virtual training programs and in the simulation of important scenarios and tests regarding key assets in factories and beyond. In other words: where the stakes are high and the value/risks are equally high.

Process manufacturing training, assembly and safety are by the way among the main use cases of VR and AR. However, across all industry use cases it’s retail that takes the lead from a spending perspective with the ‘retail showcasing’ use case, as we’ll cover next.

As mentioned, showcasing also plays a role in manufacturing, among others in design and development and in customer-facing circumstances. In the end, someone needs to convince and sell. But this of course doesn’t mean that VR and AR are just sales tools or gizmos, not in the consumer industry and most certainly not in Industry 4.0. A token of the increasing role of augmented reality in Industrial IoT is the growing support for it in several Industrial IoT platforms.

Product design, virtual training and simulations/tests with a focus on important assets, scenarios and security aspects are key VR/AR applications in Industry 4.0

Time to look at some facts and findings about the usage of virtual reality and augmented reality in manufacturing and beyond with research data, predictions and trends, before looking at benefits, solutions and a few practical applications and cases.

AR and VR trends in Industry 4.0 and beyond: the growing importance of maintenance use cases

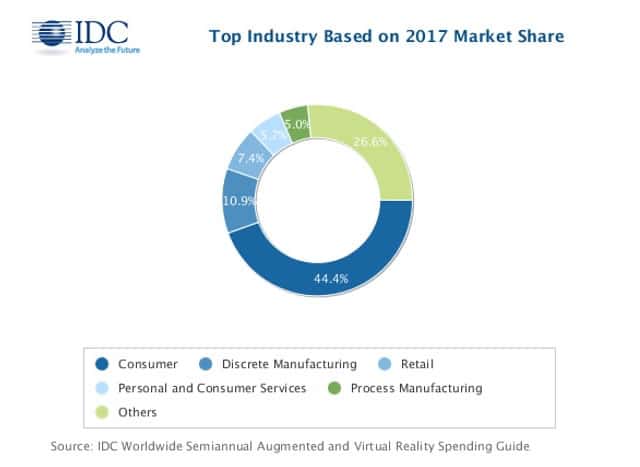

The above mentioned main industry use cases of VR/AR for 2017 are part of some takeaways of IDC’s August 2017 forecasts on the worldwide spending on augmented and virtual reality.

In that forecast IDC predicts that global spend on AR and VR will double each year through 2021, which is pretty impressive. However, given the broad scope of VR and AR use cases across several industries this obviously doesn’t only fit in a context of manufacturing and Industry 4.0.

In each of the regions IDC looked at, the consumer segment is poised to be the largest in 2017. However, in the US and Western Europe, discrete manufacturing and process manufacturing already rank second in third.

In the US, process manufacturing and discrete manufacturing are predicted to take over the consumer segment in the forecast period, along with government, retail, construction, transportation and professional services. In Western Europe, discrete manufacturing, retail and process manufacturing are predicted to start growing fast by the end of the forecast (until then the consumer segment remains largest).

If we look at the key use cases for VR/AR we also see evolutions with a strong role for industrial use cases. As mentioned previously, in 2017 the three major VR/AR use cases from an investment perspective are respectively:

- Retail showcasing, accounting for a total investment of $442 million.

- On-site assembly and safety, worth a total spend of $362 million.

- Process manufacturing training as the number three with $309 million.

By the end of the forecast, however, the majority of spending will go to industrial maintenance with $5.2 billion and public infrastructure maintenance with $3.6 billion. And that of course brings us close to one of the key aspects of the Industrial Internet of Things, Industry 4.0 and so forth: maintenance, preventive and predictive. In other research, which we covered in our article on Industry 4.0 trends, drivers and spending evolutions, preventive and predictive maintenance were mentioned as main priorities.

Again, the number of applications for VR/AR is very broad and manufacturing, transportation, logistics (Logistics 4.0) and other markets in today’s current 4.0 scope are far from the only ones. Moreover, in some regions AR and VR predominantly will keep seeing investments in, among others, the consumer segment and retail. Education is often mentioned as well. In the APeJ region it’s already the third most important ‘sector’ in 2017 according to the mentioned IDC research. The link with training in any given manufacturing context is quickly made.

Yet, it’s clear that the usage and types of applications with VR/AR in manufacturing and related industries increase with a current focus on training and safety, to name just two, and an increasing focus on discrete manufacturing, process manufacturing and maintenance in the US and Western Europe.

Make your business case for AR and VR

In a previous update (February, 2017) of its Worldwide Semiannual Augmented and Virtual Reality Spending Guide, IDC’s Tom Mainelli rightfully stated that “AR and VR headsets get most of the media attention right now, but the hardware is only as good as the software and services running on it”.

Truism. In an Industry 4.0 context we can add that the use cases which will thrive are those generating the highest value, enabling to avoid risks, issues and downtime the most, optimizing the end-to-end manufacturing process and workflows in the best possible way, making productivity, satisfaction and making experiences of field engineers, factory workers, customers and stakeholders the most satisfactory – and immersive in ways that make sense. And that goes beyond just the technological dimensions and requires an individual business case – as always.

The graphic from the announcement of that semi-annual update below shows the predictions of IDC per AR/VR industry from a spending perspective for 2017, showing the ‘place’ of process manufacturing and discrete manufacturing in the bigger picture and isn’t related to the forecasts mentioned for the next years.

Top image: Shutterstock – Copyright: Zapp2Photo – All other images are the property of their respective mentioned owners.