In an increasingly real-time economy speed and timing are key. It might sound obvious but the consequences for supply chains, logistics and the transportation industry are huge.

Efficiency, optimization, speed and timing have always been crucial in logistics and transportation. Today, amidst a range of accelerating evolutions and in an increasingly digital environment where digital transformations and the rise of IoT are driving the next revolution of industry, known as Industry 4.0, it is even more so.

In this overview we take a look at the main challenges regarding digitization and digital transformation in (goods) transportation and logistics (T&L) and, inevitably, the digital supply chain.

Speed and timing as a competitive advantage in an increasingly real-time economy

First, let’s briefly look at the importance of speed and timing in general as they are essential everywhere. Feel free to skip this part and go to the topics you’re most interested in, using the table of contents above.

Over 70 percent of executives are in high or very high agreement that the shift towards a real-time economy affects their organizational structure.

We’ve tackled how speed often is a key differentiator in today’s ‘digital business‘ context before. When used well, speed is a competitive advantage. We also mentioned how real-time economy evolutions affect organizations in another article.

Research shows how 76.9 percent of executives agree or highly agree that the evolutions towards a real-time economy has an impact on their business processes. And, obviously, in transportation and logistics (and supply chains), processes are ubiquitous and hyper-connected. A majority of executives also feels that the move to a real-time economy affects their organizational structure and business strategy.

This shouldn’t be that surprising and we’re pretty sure that if today the same research would be conducted (it dates from end 2013), the results would even be higher.

The human and connected drivers of faster business

Among the many drivers are obviously consumers, users, in other words people, who are expecting more and are increasingly mobile. This goes for all industries and in transportation and logistics, customer experience and engagement rank high in the top priorities as well.

Several evolutions, including mobility, enabled a shift in behavior which is further enhanced by the experiences customer are used to in other contexts than the interactions and transactions with your business.

CEOs see mobile technologies for engaging with customers, cybersecurity tools and data analytics as the three most important areas in which to invest. Source:PwC

It’s the famous ‘spill-over effect’. At the edge of each supply chain sits an end customer just as, at the edge of each process sits a user, a logistics partner or any other stakeholder. The focus on the customer or as Forrester calls it, the customer-obsessed operating model, is felt everywhere.

Just think, for instance, how in the context of a customer-adaptive enterprise the big data focus has moved towards fast data. Or how we move towards the edge in data analysis (edge computing and fog computing) in a context of the Internet of Things (IoT). Or how capturing and processing information fast is essential (without forgetting the accuracy). Real-time economy might be a bit of a misnomer as real-time first describes a capacity. Though we also increasingly see it as a reality.

Hyper-connectivity inherently comes with a dimension of acceleration and speed. The connectivity of processes, people and how it is used.

Speed and timing as challenges in logistics and beyond

So, customer expectations and competitive differentiation require speed and timing, which are drivers of several important changes in transportation and logistics, with speed being a competitive advantage.

We mentioned a few examples of when and where speed and timing are crucial in logistics and beyond. Here are a few examples of other areas where they are real game changers.

- Data-driven marketing aims to engage people at the time and in the context which makes most sense and – thus – increases conversions/actions.

- Information management, more than ever, is about living up to the credo of the right information at the right time for the right process(es), people, context, purposes and so on.

- Customer service: the demand for fast responses is higher than ever and here as well it is a lot about information and communication (at the right time, etc.) but also because of these increased customer expectations regarding speedy (and accurate) answers in a mobile world.

- The roll-out of new business models or technology deployments, taking decisions and/or product launches: you don’t want to be too soon nor too late.

In the end many of these examples are essential reasons why, as businesses, we’re so fond of big data and in this context certainly fast data and data analytics, delivered by unleashing artificial intelligence and cognitive computing on sets of data which we need to time so many things right and even in a predictive way as we do with predictive analytics.

Businesses don’t want data. They want visibility and dashboards to be fast and timely as they know it’s key in today’s digital transformation economy and realize it won’t change anytime soon, well on the contrary. And it is no different in logistics, transportation and supply chains.

Hyper-connectedness in transport and logistics

Whereas most of the previously mentioned examples have to do with information and communication there obviously also is the physical world of pallets, boxes, goods, paper documents, the books you just ordered online, the list goes on.

This brings us to the transportation and logistics industry where information management, data, analytics, visibility and king customer all play a key role.

After all, with each handling, shipping and any other treatment of goods come processes, information flows and interactions. With the lines between digital and physical blurring, few industries are so hyper-connected on all levels than those who are active in supply chains.

In the end, transport and logistics has one major task: making sure that any of the mentioned and other items arrive at the right time and place in the best possible condition.

Over a quarter of transportation and logistics companies have no digital strategy in place.

Whether it concerns distributors, end customers, transportation firms, retailers or any part of a supply chain: there is always someone waiting for something.

As in lots of real-life scenarios in a connected and globalized world, there are many parties involved to get an item from where it is manufactured to its end destination. The longer the waiting times for these parties, the longer it takes overall and the more time, resources, money and sometimes reputation can be wasted when a provider is too late and others need to wait. Obviously these delays don’t necessarily have an impact on the end destination. There is still something called warehousing and stock management and supply chain management is far more complex than depicted here. Just imagine all the processes that one party in the supply chain needs to complete (from the reception of an item to shipping it out in its original shape and form or as part of another item at the end of a manufacturing process).

The 7Rs of business logistics accelerated

The picture is clear. In a day and age where customers want speed and have increased expectations, the transport and logistics industry is challenged by just-in-time and near-real-time expectations.

This is not just because of the end customer or various intermediaries, it’s also because of costs, regulatory requirements and increasing competition, to name a few.

No wonder that disruptive companies such as Amazon and also newcomers focus on speed and often aim to take more control of parts of the supply chain or simply cut intermediaries where they can.

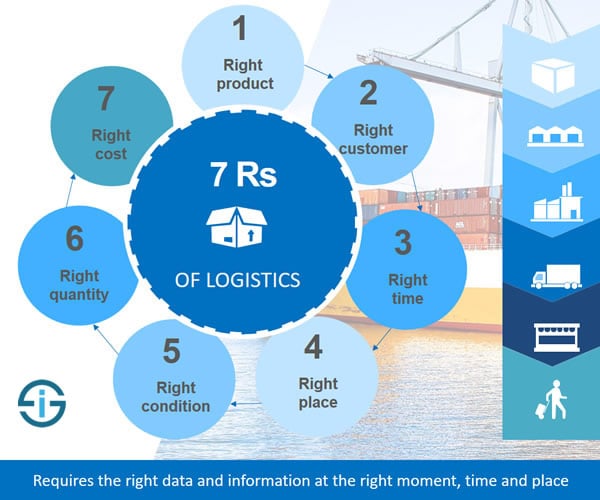

Obviously this aspect of speed and time isn’t new for the logistics and transportation industry. After all, the 7Rs of business logistics go back a long time: the right product/item in the right quantity to the right customer in the right condition at the right place, right time and right cost, right?

In today’s digital business reality most good old rules of logistics and supply chain management still are valid but the stakes are higher than ever. And it just moves faster and is far more integrated with interconnected processes and obviously data from several sources.

In fact, if you look at those 7 Rs of business logistics you immediately see how the right data at the right time, place etc. plays a key role. And we’re talking data from sensors (condition, place,…) as well as data and information in many other areas too here, including insights based upon data analytics or digitized information across the supply chain.

Digital supply chains and digitization/transformation

Digital business requires digital supply chains. Digitization (document to process) is a must and also changing the game (even if there is still a lot to do).

- Profound digital transformation is occurring in several areas and challenge the status quo.

- Innovative uses of technologies in areas such as data analytics, the Internet of Things and the cloud are disrupting existing players.

- Various parties in the supply chain move at different speeds and changing expectations and evolutions in the digital transformation economy (or fourth industrial revolution or Industry 4.0 or whichever term you prefer) simply make digitalization a necessity across the logistics, transport and manufacturing industries where digital and always-on supply chains are becoming the new norm. More about that in our article on Logistics 4.0.

Although transportation and logistics management is a really broad area (even if we leave transportation people and animals out of the equation and mainly focus on goods here), there are several evolutions which apply to the sector as a whole and de facto lead to digitization and digital transformation as key catalysts and consequences with several digital technologies to make it all possible.

Data and information at the core: digital technologies in transportation and logistics

The technologies are different, depending on the exact ‘activity’ (packaging is not the same as actual transportation or border procedure management, to name a few) but they all have one element in common: the focus is mainly on data and information.

Data and analytics are key to speed up processes, offer visibility to partners and customers, digitize value chains and, in a context of digital transformation, come up with new business models. In many sub segments of transportation and logistics, it’ about disrupting or being disrupted with data and information at the core.

This immediately makes it clear which are the several digital technologies that play a role in the industry. Most of them revolve around location, connection of devices (Internet of Things), big data analytics, cognitive computing and obviously the platforms where data are captured, processed and leveraged/accessed such as mobile platforms, information capture and processing platforms but also the networks and data environments such as the cloud.

Approximately 20 percent of digital transformation costs will be allocated directly to supply chain transformation.

Last but not least, as we are talking about business assets, both the goods and the data, security (digital and physical) is also high on the agenda with an increasing use of technologies in the space of authentication, biometrics and asset tracking, one of the main applications in the Internet of Things.

Why and how digital transformation (and digitization) matter in logistics and transportation

Below are several reasons why the transportation and logistics sector needs to – and is – digitally transforming and still has several digitization challenges of well.

First things first: digital business transformation is happening in supply chains.

Gartner’s Peter Sondergaard stated that, we quote, “in leading organizations, one quarter of enterprise costs will be devoted to the digital transformation.” Of these investments approximately 20 percent will be allocated directly to supply chain transformation, Sondergaard added.

Below are several challenges to tackle and evolutions affecting the T&L industry (on top of the previously mentioned customer expectations which are key in all industries).

The pressure on margins requires digitization, automation and a focus on new models

Cost reduction and growing profitability is essential. The margins in transportation and logistics are under pressure. This isn’t new but it remains a problem.

If we look at the period between 2005 and 2012, we see that, according to Olivier Wyman there was an average growth of 7 percent per year (revenues) but profitability (EBIT margin) declined from 6.8 percent to 4. percent in that same period.

New business models, enabled by digital technologies and focusing on the creation of solutions and value-added services, on top of cost reduction, are driving digital transformations.

The essential function of the supply chain: enhancing security to minimize risks and interruption

Business interruption, including supply chain disruption, is perceived as the number one global business risk.

It’s clear that supply chains are crucial for all businesses and the global economy as such. So it doesn’t come as a surprise that making sure it is not interrupted ranks high on the agenda.

As the Allianz Risk Barometer 2016, which we covered previously, indicates, Industry 4.0 is not just seen as an opportunity but also as a challenge, especially from the security perspective. As everything gets interconnected, so does risk. Or as Hugh Burgess, Global Head of Mid-Corporate and Head of Corporate Lines North America, AGCS, put it in the report: ” interconnectivity of risk is growing day-by-day, as technology, globalization and social change create a complex web of relationships and interdependencies with “just-in–time” and “lean” manufacturing now standard practices.”

It’s obvious that cybersecurity and IT security in general are key in supply chains and several technologies are being increasingly adopted to minimize risks and pro-actively turn Industry 4.0 challenges into opportunities.

Tackling the challenges of hybrid supply chains

According to Capgemini Consulting most organizations today still operate on hybrid supply chain models. In other words: paper-based and IT-supported processes are combined.

Paper is a huge challenge in the optimization of supply chains because it is simply too slow and, as Capgemini reminds, only available locally. Moreover, certainly in a context of complex supply chains with a lot of intermediaries and processes, documents get lost, damaged or corrupted in several ways.

It comes with risks (including fraud), a lack of visibility (what we need in supply chains today) and inefficient processes and suboptimal resource allocation to name a few. Digitization is still a big challenge in transportation and logistics and there is ample room to optimize processes and capture information close to the source or point of ‘action/origination’ to speed up processes and enhance transparency while increasing agility (remember the need for speed). Moving from hybrid supply chains to digital supply chains is one of the key evolutions in T&L.

Taking the next steps regarding data maturity

The transportation and logistics industry is information-intensive and always has been data-driven.

However, the big data and data-driven traditions are not a guarantee for a successful leverage of the new data realities. T&L companies need to move up the data maturity level in order to turn possibilities in the sphere of the Internet of Things and cognitive computing into benefits that enable them to transform their businesses faster than is the case today. The focus shifts from the data to the outcomes and transformations.

According to 2016 transportation and logistics research by PwC “only 10 percent of transportation and logistics companies rate the maturity of their data analytics capabilities as advanced”. This is less than in other sector, PwC states (source: “Industry 4.0: Building the Digital Enterprise – Transportation and logistics key findings”).

The Internet of Things and Everything in transportation and logistics

With big data (analytics) we inevitable need to talk about the Internet of Things. It is clear there are many things in T&L and supply chain efficiency and data opportunities, as well as visibility and new approaches, can all be accelerated by leveraging IoT applications.

There are ample examples of how the Internet of Things is revolutionizing the logistics and transportation space.

While it’s important to take a look at the future developments and latest trends (from connected and even ‘autonomous’ trucks to warehouse robotics and smart warehouse solutions overall, to name a few), reality is of course that the Internet of Things has been around in logistics, transport, supply chains, warehousing etc. since quite some time.

Let’s not forget that the Internet of Things and its roots in RFID in more than one sense started in logistics, warehouses and the supply chain in general. The Industrial Internet of Things is a key component of the ‘connected logistics market’ as you can read here.

Asset management is one of many applications where RFID and the IoT have been present since quite some time as part of end-to-end inventory and asset management solutions. The combination of sensors, connected devices, big data (analytics) and mobile/cloud/connectivity technologies is adding additional possibilities to asset tracking and management. As an example, on top of simply tracking your inventory, palettes, crates, shipments and fleet, information can be gathered regarding the state of any connected item, including vehicles, to take decisions in areas such as maintenance.

The list of potential IoT applications in T&L and supply chains is long and implications are huge.

Or as Gartner’s Peter Sondergaard said in the previously mentioned article on how digital business means big change for supply chains, “the focus is on how the supply chain can consume and leverage data, integrate sensors and other elements of the Internet of Things (IoT) and software for customer segmentation and marketing automation“.

Closing the gaps regarding information maturity and digital capabilities

This overview of challenges and drivers is not exhaustive. There are several other evolutions and challenges, certainly when we look deeper into various aspects of the broad field that T&L is.

Improving connectivity across the full chain, the possibility to better predict and forecast, several regulatory challenges, newer technologies such as drones and 3D printing, changes in logistics patterns and scenarios as depicted in the graphic from PwC below, challenges regarding resources (people, management but also energy, for example), integration of value chains, the list is long.

However, before looking at what the future holds (and what is already happening in several companies) it’s key to get the house in order.

And that’s not just about digital technologies as challenges, ‘protectors’ (security), enablers and accelerators, based upon mobile, cloud, big data and the Internet of Things.

It’s also about culture and dealing with the essential challenges with regards to be fully digitally ready. If you look at the many digitization challenges, from paper-based proof of delivery (POD) documents to a lack of visibility, you know there is still a lot to do.

As the Digital Pulse Survey from Russell Reynolds Associates found, over a quarter of T&L companies still doesn’t have a digital strategy in place.

Moreover, 80 percent report that the CEO does not recognize the potential for digital while in 80 percent of companies digital business implementation is also hindered by departments who are competing for the ownership of digital, not exactly what we like to see.

As newcomers enter the market, T&L companies have an opportunity to offer new services and even new types of business themselves. It works in two ways and several players already started moving beyond their core business. The time to connect the dots and leverage hyper-connectivity, moving away from silos to data maturity and digital strategies which encompass the whole business is now.

Digital capabilities and information excellence are key to close existing gaps and transform for better customer engagement, new business models and the challenges facing the industry.

Top image: Shutterstock – Copyright: TTstudio – All other images are the property of their respective mentioned owners.