Industry 4.0 leader Rockwell Automation announces that it will be present at Hannover Messe 2017 on several booths of its Strategic Alliance Partners.

The Milwaukee-based global player in smart manufacturing and industrial automation will specifically focus on the Industrial Internet of Things (IIoT) and digital transformation (in manufacturing).

Rockwell Automation offers productivity enhancement solutions across the automation lifecycle with product offerings for, among others, advanced process control, human machine interface, industrial network products and sensors, PLCs, safety and security, condition monitoring and design and operations software.

Virtual design, MES and scalable analytics and an IIoT-enabled packaging machine on the booth of Microsoft

Rockwell Automation, which has sales offices across all continents, will join its partner Microsoft (Hall 7, Stand C40) at Hannover Messe 2017 where the company, among others will showcase a full suite of MES and scalable analytics offerings, including the FactoryTalk Analytics for Devices application.

Microsoft and Rockwell Automation will also give demonstrations of virtual design, leveraging a Microsoft HoloLens headset which works with Rockwell Software Studio 5000 development environment and enables creating a so-called mixed reality experience (simulation and digital twin).

Finally, an IIoT-enabled packaging machine from CAMA Group will be displayed. It uses a mix of Rockwell Automation and Microsoft software and technologies.

Industry-grade network architectures (CPwE and Ethernet/IP) and more at Hannover Messe 2017

On the booth of its partner Cisco (Hall 8, Stand C13 at Hannover Messe 2017), Rockwell will focus on its collaboration with Cisco with regards to industrial networking and security solutions for digital transformation.

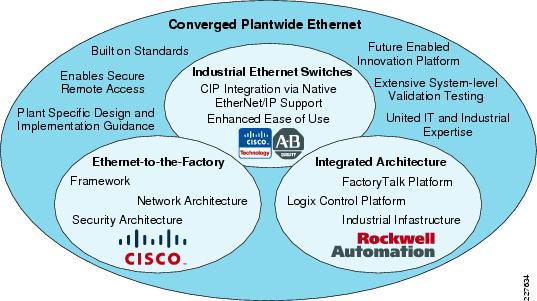

Here, attendees can see a connected Jaguar F-PACE car which was built on a production line using the so-called CPwE network architecture. CPwE stands for Converged Plantwide Ethernet and was co-developed by Cisco and Rockwell Automation. The image on the right shows a graphical depiction of the CPwE Architecture by Cisco which shows how Cisco and Rockwell Automation have collaborated on it with a respective focus on, among others Ethernet-to-the-Factory and Integrated Architecture.

Also on the Cisco booth, attendees can see a demo of MagneMotion’s MagneMover LITE independent moving cart system which brings together agile manufacturing and information gathering and is equipped with a robot from FANUC (MagneMotion is a Rockwell Automation company). Its main benefits: flexible manufacturing and increased throughput in comparison with classic mechanical conveyor systems.

On Stand C43 in Hall 11, where Rockwell Automation partner Endress+Hauser is present, the company will show, among others, process solutions and tools to reduce risk, implementation time and integration costs.

Last but not least, Rockwell Automation is also on Stand E55 in Hall 11 at Hannover Messe where ODVA is present.

ODVA developed EtherNet/IP™ , a nonproprietary Ethernet technology which enables real-time control and information in industrial settings. EtherNet/IP™ was developed in 2001 and enables the deployment of standard Ethernet (IEEE 802.3 and TCP/IP) for industrial automation while also enabling Internet connectivity for IIoT.

Quoting Tom O’Reilly, VP global business development at Rockwell Automation: “Digital transformation and initiatives like Industrie 4.0 are without a doubt a priority for manufacturers and industrial operators everywhere. With our Strategic Alliance partners, we will be showcasing how technologies like device-to-device communication and augmented reality can deliver value for companies as they embark on digital transformation and build a truly Connected Enterprise.”