How is the UK doing with the digitization and digital transformation of its manufacturing industry, which it also calls Industry 4.0 and 4IR (whereby 4IR stands for 4th industrial revolution)?

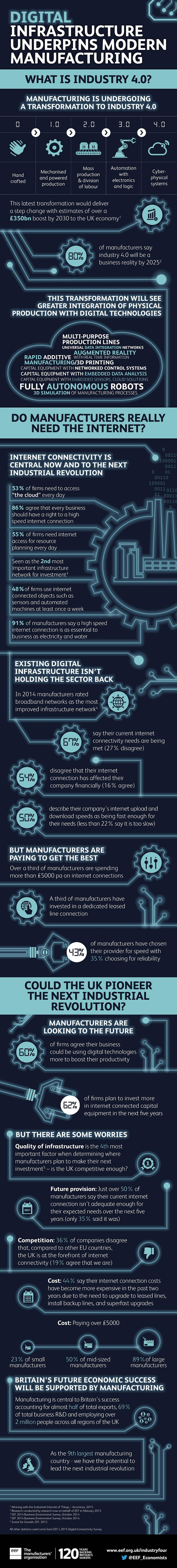

Just as in some other views, 4IR is mainly about the possibilities and transformation of manufacturing with connected data at the center and three key components: the Industrial Internet of Things, Big Data and the digital infrastructure (including networks) that makes it all possible.

When Infosys and the Institute for Industrial Management (FIR) at the RWTH Aachen University conducted global research in 2015, which would contribute to the creation of an Industrie 4.0 Maturity Index, the UK ranked third in terms of country maturity in Industry 4.0 implementation.

Although the research only looked at 5 countries, the UK turned out to score better (26 percent) than Germany (where Industrie 4.0 was invented so to speak) and better than France (with Germany and France respectively scoring 21 and 14 percent).

The clear leaders were China (57 percent) and the United States (32 percent). In other words: the picture looked good for the United Kingdom, the country where the first industrial revolution started (with Belgium being the second and first on continental Europe in those long gone days). What about today? Time to take a deeper look at the various reports and initiatives around the fourth industrial revolution in the UK.

Is the UK underprepared for Industry 4.0?

On March 30th 2017, the UK’s magazine for automation, motion engineering and power transmission, Drives&Controls, wrote that the UK is “badly underprepared” for Industry 4.0, citing a survey of 200 UK engineers by industrial services company ERIKS.

Just as is the case in virtually all countries where significant Industry 4.0 initiatives are taken, such as the US, Germany, Japan, China and several EU countries, the UK manufacturing industry shows gaps between the perceived importance of Industry 4.0 and the preparedness to take steps to move towards 4IR maturity. And, just as is the case in all those other countries, a variety of barriers exist. In that sense, the UK is certainly not an exception.

Among the many barriers (more below) in general is a lack of a strategy and a plan, which is important in an individual company context and a national context.

Regarding the latter, the EEF or British manufacturer’s organization has been taking steps in order to inform and empower manufacturers regarding the 4th Industrial Revolution or 4IR as the EFF also calls it. Did the organization find this under-preparedness?

UK manufacturers feel they are ready but the industry is not

End 2016, the EEF and Oracle published a joint primer for manufacturers. It is one of many publications and initiatives taken by the EEF as you can see on the EEF’s 4IR hub, which contains a range of publications, blogs and resources regarding the 4th industrial revolution and its various challenges and evolution in the UK.

4IR is one of the campaigns of the EEF, so Industry 4.0 also took center stage at the EEF National Manufacturing Conference 2017 which was organized in February. The video at the bottom of this article at the occasion of the event leaves no doubt about that: Industry 4.0 is what “Made in Britain, loved by the world” was all about. Moreover, if you look at the other videos from the event which have been posted at the time of writing this, three of them are views on what 4IR is. So, it clearly lives.

Back to the paper of the EEF and Oracle. One of the chapters looks at the question if the UK manufacturing sector is geared up for the 4th industrial revolution or 4IR. It showed that, once more as is also the case in other countries in this stage, manufacturers don’t feel ready for Industry 4.0.

However, quite a lot of them say they feel their business is ready but that the UK industry overall isn’t. In other words: there is a need for a more comprehensive initiative across supply chains and industrial sectors about the benefits (and the scope and journey).

Some data from the report of the EEF (also check out the data in the 2016 EEF infographic below):

- 61 percent of responding manufacturers agree that the could use digital technologies more to boost their productivity.

- 80 percent of manufacturers states that 4IR will be a business reality by 2025.

- 96 percent of manufacturers agree that the fourth industrial revolution will be about connectivity and communication.

- 61 percent of manufacturers disagree that they will find it difficult to keep pace with the change brought about by 4IR.

- 99 percent of manufacturers agree that 4IR will be about turning data into actionable insights.

- Only 11 percent of manufacturers think the UK manufacturing sector is geared up to take advantage of 4IR.

The importance of a pragmatic and holistic view and profound understanding of Industry 4.0

Turning data into actionable information as the essence of 4IR. Where have we heard that again? Indeed, turning data into actionable insights or intelligence is what so many evolutions are about.

Taking this into account it’s not surprising that so many manufacturers feel it won’t be too hard to keep pace with all the changes and the report clearly indicates manufacturers feel it’s essentially a UK manufacturing sector challenge.

While the latter is certainly true (and is one of the reasons why countries and regions have coordinated efforts or are coordinating them), we must point out that UK manufacturers don’t realize the full scope of Industry 4.0 yet, especially in the more transformational and next-level aspects where we move towards service models and innovative approaches. This seems to be confirmed in how manufacturers define 4IR in the report and in the fact that quite some technologies are not on the mind of manufacturers for the time being.

Examples, as the chart from the EEF Manufacturing Ambitions Survey 2016 below shows, include augmented reality with real-time information, 3D simulation of manufacturing processes and rapid additive manufacturing.

In other words: quite some key components of the Industry 4.0 stack aren’t seen yet. But then again: we see similar results in other countries. Transformation and digitalization is confused with optimization and digitization in manufacturing too.

The 4IR journey: looking beyond immediate goals

This doesn’t mean that the latter aren’t important. Just as digital transformation doesn’t happen just like that, 4IR requires a roadmap and step-by-step approach, driven by real challenges and opportunities as part of an ongoing journey but with an eye on the bigger picture and a profound understanding of what Industry 4.0 is and enables.

Therefore, it is good that we have things such as an Industry 4.0 Maturity Index and other frameworks. The EFF knows that and came up with a so-called 4IR Journey for UK manufacturers, consisting of three stages: conception, evolution and revolution.

The UK manfacturing industry overall (it is a phenomenon with different speeds) is mainly in the stage of conception and evolution, or in the words of the EFF: “undoubtedly not all manufacturers are at the same stage of knowledge….we are at the start of this 4IR journey and understandably, many manufacturers are still getting to grips with the subject”.

Different data and the lack of understanding

The fact that not everyone is really aware about what that 4th industrial revolution or Industry 4.0 is about is among the many reasons why we see so many different numbers in all the research about readiness.

The article in Drives&Controls, based upon the research by ERIKS states that, although 80 percent of 200 responding engineers feel that Industry 4.0 will have a positive impact on production and maintenance, 61 percent aren’t undertaking any Industry 4.0 initiatives and also points to several of the well-known barriers. The mentioned ERIKS Industry 4.0 research paper, which was launched at the occasion of the Maintec 2017 event, can be downloaded here.

On the website of the Industry 4.0 Summit 2017 in Manchester (4-5 April), we read that 83 percent of UK manufacturers are planning to invest in automation and control systems in the future, whereas only 48 percent of manufacturers across Europe feel they are ready for the future.

The organizers also point to Accenture research from 2015 which found that “an industrial-scale version of Industry 4.0 would add up to $531 Billion in the UK” (and $14.2 Trillion to the world economy). We checked the Accenture Research out to be sure. Those numbers are indeed correct, however there are two things to point out: 1) to reach this number additional measures need to be taken, otherwise it’s probably $303 Billion and 2) the research – see chart – looks at the opportunity of the Industrial Internet of Things (IIoT). While the Industrial Internet of Things is key in Industry 4.0 and both are often used interchangeably it is not correct to do so.

In June 2016, BDO stated that Industry 4.0 could be a game changer for UK manufacturing but that it’s less known and developed in the UK. So, it conducted a survey with the Institution of Mechanical Engineers (IMechE), finding that only 8 percent of UK manufacturers have a ‘significant understanding of Industry 4.0 processes’, although 59 percent states the impact on the industry will be big.

All these reports do seem to find significant differences, depending on whom creates them. Yet, looking at all the other data from the BDO research, we’re pretty sure that, as BDO also says, there is a lack of understanding.

Pushing the agenda – an industrial transformation strategy for the UK

Whether this lack is bigger in the UK than in other countries is another story and research is research but it’s clear that the industry needs to be better informed, needs a plan and seeks initiatives. And that’s exactly what came out of the EFF initiatives.

Moreover, let’s not beat around the bush, as Information Age reported end March 2017, looking at yet another report and again other findings on the state of digital transformation and Industry 4.0 in the UK, the British industry has a barrier towards adoption that is pretty unique.

It’s called Brexit and half of participants in the tackled survey stated that it is already making it harder to justify investment in digital transformation. According to the same article and research Brexit is also causing uncertainty and further contributing to an Industry 4.0 skills gap.

Regardless of Brexit and of national reflexes in virtually all parts of the world: manufacturing and industry is a global given and it’s key that collaborations beyond the political debates occur because one thing is for sure: Industry 4.0 will happen.

That’s why end January 2017 the UK government kicked off an initiative to have an industrial transformation plan and strategy and respond to the fact it was seen as lagging behind.

The Industrial Digitalisation Review as the initiative was called was chaired by Siemens UK and Ireland CEO Jürgen Wolfgang Maier.

Along with his team of collaborators and over 200 organizations he set out for a highly ambitious strategy with regards to 4IR, which resulted in the so-called Made Smarter Review that, on top of a thorough analysis, contains recommendations to bring the UK to the top of 4IR across the globe.

The Made Smarter Review got published end October 2017. It’s a highly recommended read with projections for impressive growth by 2025 and 2030 if obviously the recommendations are followed.

Here is the promised, somewhat older EFF infographic on Industry 4.0 in the UK.

Top image: Shutterstock – Copyright: Christian Lagerek – All other images are the property of their respective mentioned owners.