Siemens is further expanding its additive manufacturing (AM) portfolio with the acquisition of US-based software developer Atlas 3D. Sunata, Atlas 3D’s cloud-based software, works with Direct Metal Laser Sintering (DMLS) Printers. The Industry 4.0 giant also opened its Additive Manufacturing Network.

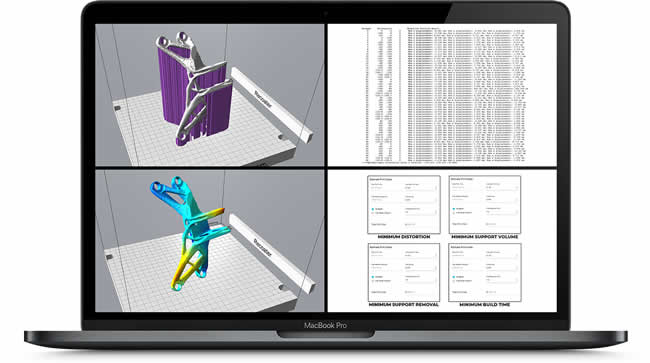

Atlas 3D’s software solves two important contributors to thermal distortion, the number one issue that hampers successful first prints in metal additive: part orientation and support structure integrity. Sunata automatically chooses the best orientation for a part and generates the necessary support structures for ‘right first time’ 3D printing.

The high rate of 3D print failures is a key challenge for companies that want to leverage additive manufacturing for high-volume production. Parts often need to go through several design and analysis iterations before the optimal build orientation, and support structures are determined.

GPU-accelerated high-performance AM software enabling front-end designers to get closer to a successful first print

Designers usually don’t have the capabilities to consider such factors as part orientation, distortion, and heat extraction uniformity in their design, leaving the solving of such issues to engineering specialists.

With Sunata, front-end designers, however, have a quick, automated and easy way to do it themselves. Sunata is a GPU-accelerated high-performance computing additive manufacturing software solution that can deliver results up to one hundred times faster than other build simulation solutions on the market. The terms of the transaction were not disclosed, and the acquisition closed in November 2019.

The Atlas 3D team joins Siemens Digital Industries Software, the new name (since September 2019) of Siemens PLM Software, where its solutions should expand the additive manufacturing capabilities in the Siemens Xcelerator software portfolio.

Expanding the AM capabilities of the new Xcelerator portfolio

This integrated portfolio of software, services, and application development platform was announced in September 2019. Xcelerator combines the core Siemens Digital Industries Software portfolio with the Mendix multi-experience application development platform

Xcelerator combines Siemens’ digital twin technology with its Mendix low-code development platform ‘to power digital transformation and make it possible for anybody to easily build, integrate and extend existing data and systems’. It integrates solutions for PLM, Electronic Design Automation (EDA), Application Lifecycle Management (ALM), MOM, embedded software and IoT (with its MindSphere IIoT platform).

Siemens will make the Atlas 3D solution available through its online Additive Manufacturing Network.

Launch of the Siemens AM Network

This Siemens AM Network was also officially launched in November and provides a cloud-based solution to foster collaboration and process orchestration between engineers, procurement and suppliers of 3D printed parts.

Early adopters already realized the benefits of the AM Network that ran in pilot mode and was implemented with some customers and partners, such as Decathlon, Siemens Gas & Power, Siemens Mobility, HP, and Materialise.

The AM Network, part of Siemens’ suite of SaaS solutions, for instance, is used by sports retailer Decathlon to manage their AM ordering process and control production progress as part of their strategy to scale their use of 3D printing globally and ramp up production while maintaining high standards of quality.

Back to the acquisition of Atlas 3D with the comments from CEO Chad Barden on the acquisition: “Siemens is a leader in additive manufacturing, with the most integrated and functionally robust solutions in the industry, so we are excited to join the team. The power of Sunata is that it equips designers to more easily design printable parts, which helps companies more quickly realize the benefits of additive manufacturing. As part of Siemens, we look forward to introducing Sunata to customers who already have Siemens’ AM solutions and can achieve new efficiencies in their front-end design-for-additive process, as well as companies who have yet to start their additive manufacturing journey”.