Industrial AM (additive manufacturing) and industrial 3D Printing in evolution at IN(3D)USTRY – from needs to solutions and evolutions.

Additive manufacturing (AM) and 3D printing might not be the most mentioned of the whole Industry 4.0 range of technologies/applications but it’s certainly one of the most exciting, promising and ground-breaking evolutions, even if it will still take some time, innovation and problem-solving before it becomes more broadly adopted.

3D printing/additive manufacturing is an innovation accelerator

Additive manufacturing and 3D printing, though used interchangeably, don’t mean the exact same thing. Well, they overlap in many ways and are one and the same in several senses: building parts and objects based upon layers of several possible materials, using several possible techniques and for several possible applications, industries and purposes (which determine, among others the used materials and so forth).

Industrial additive manufacturing or 3D printing – confusions and terminologies

Still, they are not fully the same, to say the least.

It’s not just about the fact that they are different in several regards, even if they have many common characteristics (e.g. the fact that they are based upon manufacturing methods using layers), it’s also about how the terms are used. You might read about 3D printing in a consumer context, you won’t read about additive manufacturing in that same context.

Anyway, all this might be food for other articles but it is what it is: 3D printing is used as a synonym for additive manufacturing, whether we like it or not. Yet, do keep the differences in mind when reading reports on the market, for example. IDC, for instance has added 3D printing to its lists of so-called ‘innovation accelerators‘ since quite some time now – although these innovation accelerators on top of its 3rd platform are not bound to an industry.

Yet, when we look at the title of its March 2017 Market Perspective we see that IDC called it 3D Printing/Additive Manufacturing “Ones to Watch,” 2017. Quoting research director Tim Greene: “3D printing/additive manufacturing has been identified by IDC as an innovation accelerator”.

On our Industry 4.0 overview page you can see how the Boston Consulting Group speaks about additive manufacturing as one of nine digital industrial technologies, adding 1) “3D printing, particularly for spare parts and prototypes” (prototyping and rapid prototyping are important in the whole 3D and additive equation) and 2) “decentralized 3D facilities to reduce transport distances and inventory”.

Gartner defines additive manufacturing as “the capability to create a physical object from a digitally encoded design through the deposition of material via a 3D printing process”, while 3D printing is defined as “an additive technique that uses a device to create physical objects from digital models”. The devil is in the details.

Industrial AM and 3D Printing at IN(3D)USTRY

The market is moving fast as IDC’s Tim Greene says, yet that’s not everywhere and always the case and it’s moving much slower with regards to adoption.

In February 2017, IDC published a press release stating that in Europe, the aerospace and healthcare industries lead 3D printing adoption for finished part manufacturing but at the same time points out several barriers for the 3D printing industry on the level of:

- materials,

- hardware,

- knowledge,

- regulatory compliance and

- a lack of industry-specific solutions.

Lighter parts, more complex structures, cost-effectiveness on short runs, and more flexibility are some of the benefits mentioned by users when comparing 3D printing to molding and subtractive technologies (IDC press release)

In the meantime, additive manufacturing as such keeps evolving; again it is a very exciting field to be in today and we’ve seen some remarkable innovations and applications in additive manufacturing and INDUSTRIAL (terminology problem partially solved) 3D printing, as well as other models.

If it’s all still a bit confusing and challenging but you want to know what exactly exists and can be achieved, including success stories, you might want to pay a visit to “IN(3D)USTRY From Needs to Solutions” or check out some of the videos (more below).

IN(3D)USTRY is an event that solely focuses on additive manufacturing and advanced manufacturing and takes place at the same time as the IoT Solutions World Congress. IN(3D)USTRY is also one of the eight events of the Barcelona Industry Week.

The show’s director, Miquel Serrano, promises that “the second edition of IN(3D)USTRY From Needs to Solutions is aiming to be the meeting point for identifying the challenges posed by companies from the automotive industry, aeronautics, the retail sector and healthcare and the solutions offered by all the players within these sectors, from printer manufacturers to software developers and the creators of robots, for example”.

Below is one of the better presentations in the context of manufacturing from the first edition of the event.

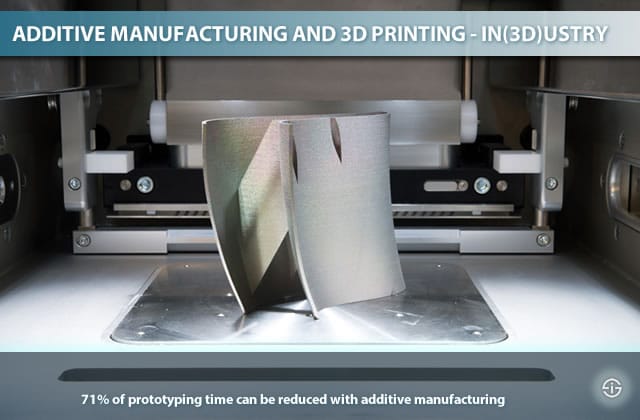

The image above on top of the page shows a metal 3D printer. Direct metal laser sintering or DMLS is another additive manufacturing technique which uses a Ytterbium fibre laser fired into a bed of powdered metal. Copyright: Moreno Soppelsa – All other images are the property of their respective mentioned owners.